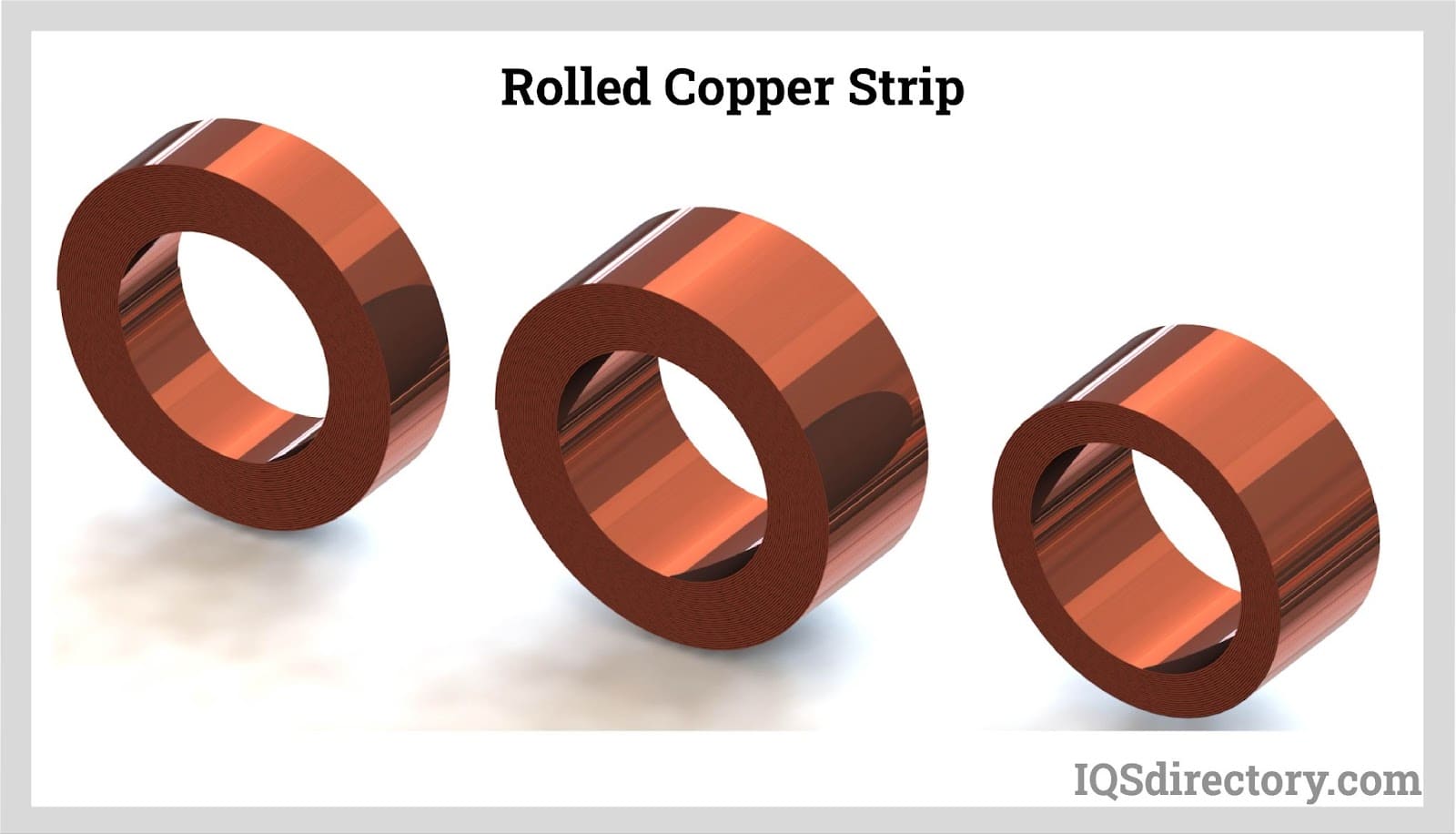

Copper strip is a rolled copper material that ranges in thickness from 0.5mm (0.019685 inches) to 10mm (0.393701 inches). Based on the company manufacturing it, copper strip may also be known as brass strip, bronze strip, red copper strip, or white copper strip. Read More…

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

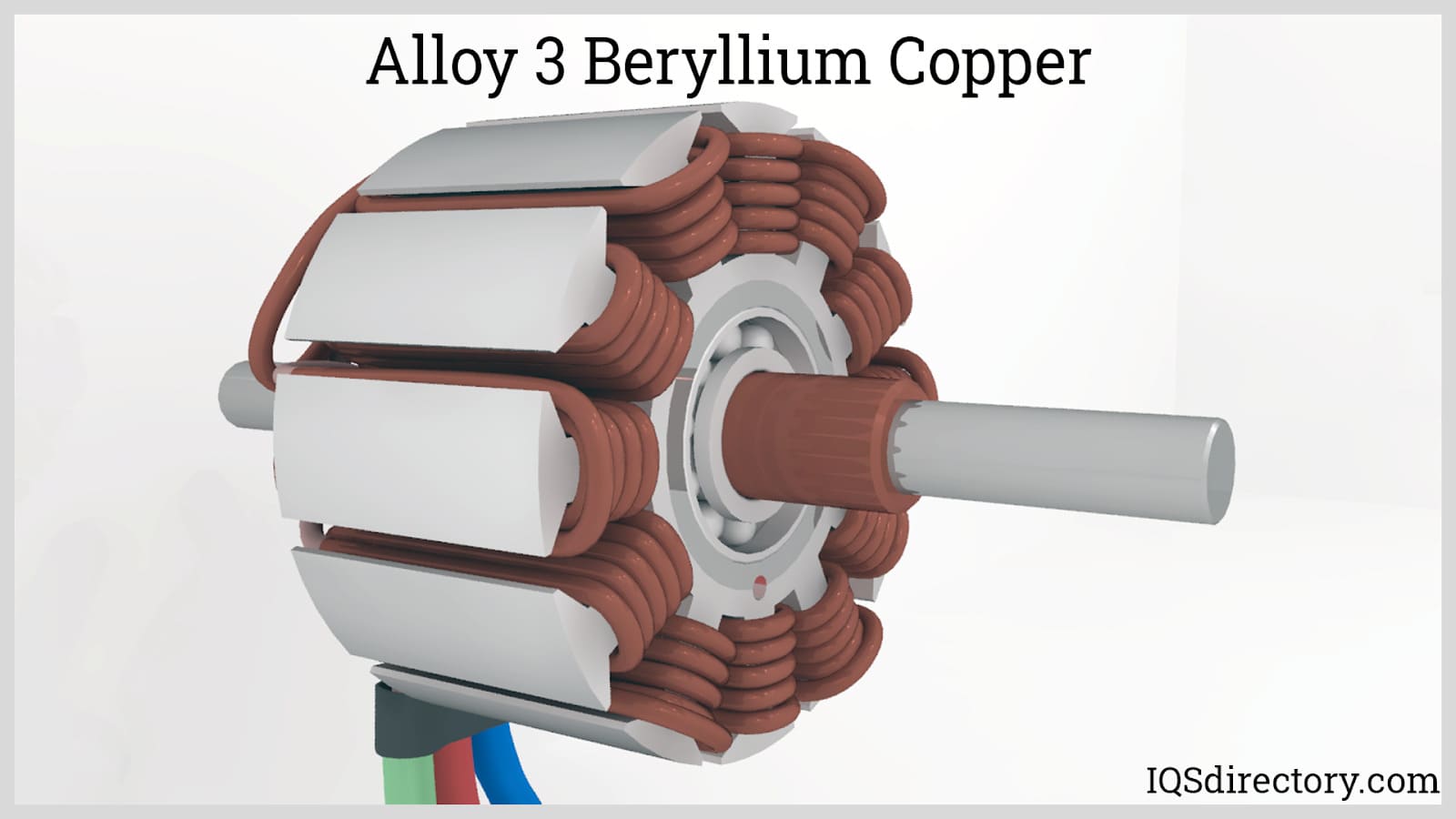

With over 25 years of metallurgy experience we guarantee we can produce exactly what you are looking for. We offer fast delivery and a multitude of beryllium copper sizes. Our highly knowledge staff takes great pride in creating these outstanding copper alloys. We have a reputation of manufacturing the best copper fabrications. Our company has risen in the standard in copper processing. Contact...

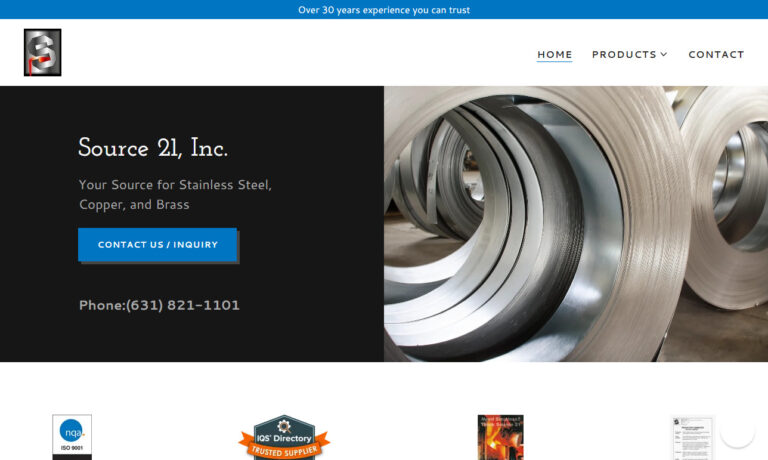

At Source 21, Inc., we take pride in offering top-notch copper products to meet a wide range of industrial and commercial needs. When it comes to copper, we've established ourselves as a reliable provider known for quality, accessibility, and customer satisfaction. Our extensive array of copper products is designed to cater to your diverse requirements while ensuring uncompromised excellence.

At Concast, we have no problem fulfilling your needs for bars, tubes & shapes in copper alloys. Our complete standard line includes leaded Red Brass, Leaded Tin Bronze, Manganese Bronze, Aluminum Bronze & Extruded products. Plus, special alloys and custom sizes and shapes are easy to quote and to order. When it comes to inventory, we have no equal; we stock more than 875 standard product sizes.

We have history from the American Revolutionary War through today. We are an ISO 9002-certified plate mill. Our copper and copper alloy product selections include copper bar, copper plates, copper sheets, copper strips and extruded profiles. Ask about our brass plates and bronze alloys, too.

More Copper Strip Suppliers

Copper Strip Production

The manufacturer transforms the ore from its unprocessed, mined state into a purified version for use in numerous industries. Oxide and sulfide ores that contain between 0.5% and 2.0% copper are commonly used to extract copper. Copper producers use different refining methods depending on the type of ore, as well as other economic and environmental factors. Currently, sulfide sources account for around 80% of the world's copper production. Copper processing is a complicated process that requires numerous steps. Let’s look at this process further.

Stage 1: Melting Down Copper

Today, copper is typically melted down in an electric furnace known as an induction furnace where they are better able to reach and monitor the required temperature for melting this ore; copper has a high melting point of 1083°C (1981°F). Induction furnaces are extremely pricey industrial equipment, but they do ensure a level of safety that is not present in foundries that are self-built. Typically, copper is melted down by itself but, occasionally, other materials such as zinc may be added to create a copper alloy.

Stage 2: Laboratory Test

Next, blocks from each batch of copper are sent to a laboratory where they are inspected to guarantee that specific customer requirements and product specifications are met.

Stage 3: Cutting

After each batch is approved, it is formed into a copper strip. The entire copper strip is then placed on a cutting table, and cut off using a cutting wheel saw. Then the copper strip's uneven surface is smoothed using a copper strip surface washing machine, which is advantageous for the copper strip's later-processed surface for smoothness and flatness.

Stage 4: Hot Rolling

Next, the copper strip is heated at a temperature of 1,000 °C (1,832 °F), and then rolled to ensure a uniform thickness and create a more workable material.

Stage 5: Washing With Water

There are still surface impurities after the hot rolling process is applied to each copper block. As a result, it is first subjected to the sealing furnace and then the washing procedure is undertaken in order to prevent the completed product's quality from being impacted. Then, the dark red areas are eliminated by a fine metal brush during washing and the middle red sections on the copper strip's surface are washed away by the acidity in the washing pool.

The copper strip clearly sparkles following this round of treatments. However, there are frequently still red plaques, so it is critical to repeat the washing stage. The washing pool’s acidity is regularly checked during the washing process and acid is added as needed in order to prevent the acid level from being too low and causing insufficient washing.

Stage 6: Rolling the Plate

Finally, the copper strip is heat treated and forged inside a sealing furnace, then processed to go from a rough to a fine material of specified size.

Copper Strip Types

Copper strips come in a variety of thicknesses and diameters. These strips provide numerous advantageous qualities and, as a result, are ideal for a variety of application needs. Let's examine the various types of copper strips produced, the benefits they provide, and where they are utilized.

Bare Copper Strip

Bare copper strip is known for its longer service life, precise engineering, dimensional control, and crack-free bends. While these strips' available widths range from 6 mm (0.23622”) to 359 mm (14.1339”), their thicknesses range from 0.01 mm (0.000393701”) to 60 mm (2.3622”). These strips are frequently found in automatic machines where they are employed primarily for their capacity to enhance production. Due to its conductivity, production facilities use copper strips as raw materials in a variety of equipment including machine parts, generators, transformers, and appliances. These strips are renowned for their ability to resist corrosion and they are frequently used by production businesses that are based in areas with high soil salinity levels. These strips are most frequently used as switch terminals, electrical contacts, electrical conductors, and electrical circuits in such conditions.

Enameled Copper Strips

Enameled copper strips provide many beneficial characteristics including durability, flexibility, tensile strength, and resistance to heat, water, and weather. Due to these traits, enameled copper strips are mostly utilized for insulation. However, their exceptional performance value supports a variety of additional applications. They are most frequently used in a variety of switch gears and oil field transformers. Numerous companies also employ enameled copper strips for binding. These strips are also used to connect a variety of components including electric motor stators, high-voltage motors, and specialized transformers.

Benefits of Copper Strips

- They require almost zero maintenance once installed.

- Copper strips have a capacity to function even under adverse weather conditions.

- Copper strips provide excellent electrical conductivity.

- They feature greater toughness and corrosion resistance than other materials.

Choosing the Proper Copper Strip Manufacturer

To make sure you have the most positive outcome when purchasing Copper Strips from a Copper Strip Supplier, it is important to compare at least 4 or 5 Companies using our list of Copper Strip manufacturers. Each Copper Strip Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Copper Strip company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Copper Strip companies with the same message.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services