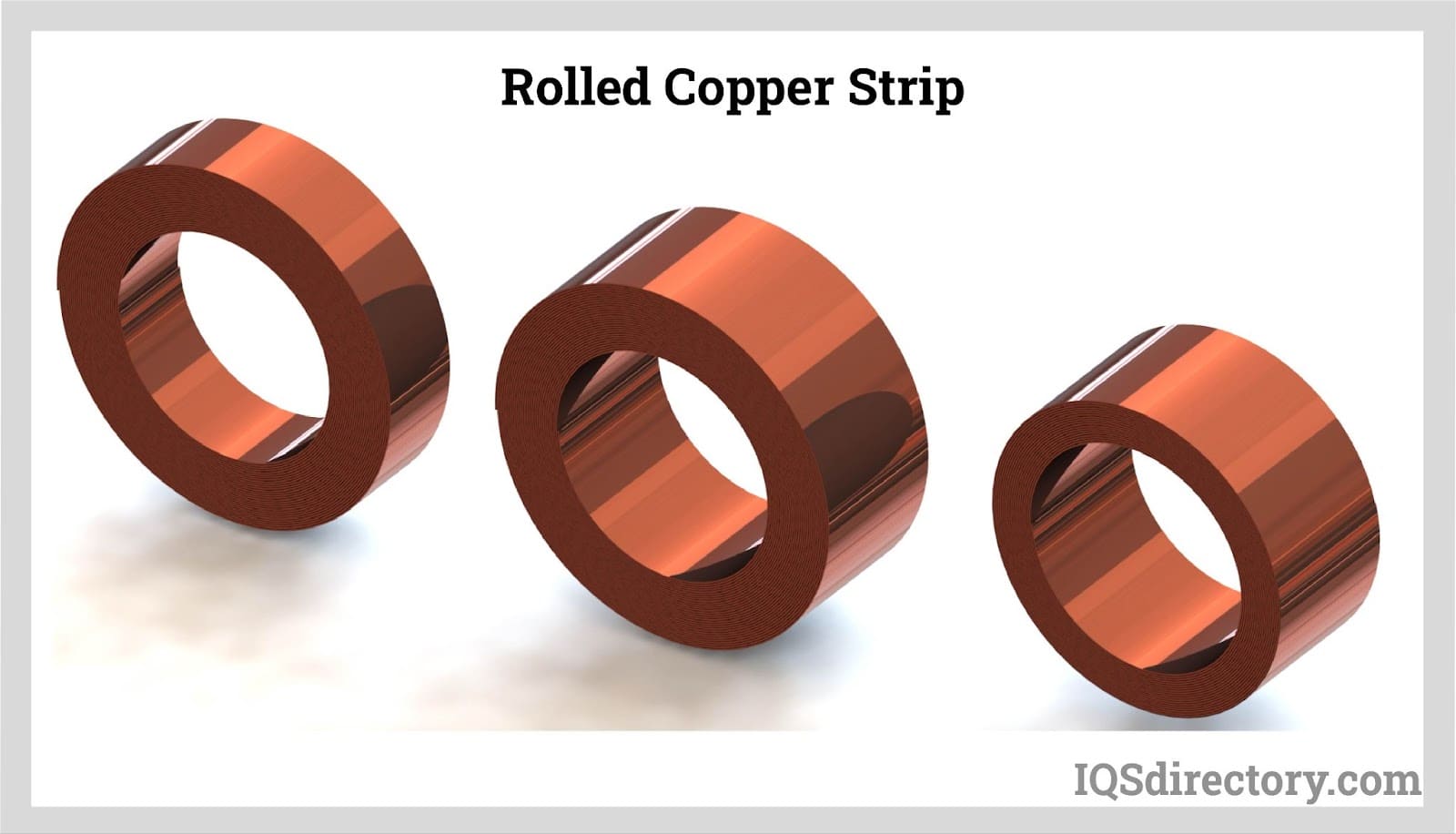

Copper strip is a rolled copper material that ranges in thickness from 0.5mm (0.019685 inches) to 10mm (0.393701 inches). Based on the company manufacturing it, copper strip may also be known as brass strip, bronze strip, red copper strip, or white copper strip. Read More…

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

With over 25 years of metallurgy experience we guarantee we can produce exactly what you are looking for. We offer fast delivery and a multitude of beryllium copper sizes. Our highly knowledge staff takes great pride in creating these outstanding copper alloys. We have a reputation of manufacturing the best copper fabrications. Our company has risen in the standard in copper processing. Contact...

At Source 21, Inc., we take pride in offering top-notch copper products to meet a wide range of industrial and commercial needs. When it comes to copper, we've established ourselves as a reliable provider known for quality, accessibility, and customer satisfaction. Our extensive array of copper products is designed to cater to your diverse requirements while ensuring uncompromised excellence.

At ABC Metals, we are dedicated to delivering high-quality copper products that meet the diverse needs of industries worldwide. We work with a wide range of copper materials, from pure copper to specialized alloys, to provide solutions that excel in conductivity, durability, and corrosion resistance.

At Southern Copper & Supply Company, we have built our reputation on delivering high-quality copper products and dependable supply solutions to meet the diverse needs of our customers. We specialize in sourcing, processing, and distributing copper in various forms, from raw stock and sheet material to precision-cut and custom-fabricated components.

More Copper Strip Suppliers

Copper Strip Production: Comprehensive Guide to Manufacturing and Applications

Copper strip production is a critical process that transforms raw copper ore into a refined, highly-conductive material used across a wide array of industries. As a top copper strip supplier or manufacturer, understanding the production process, quality control, and application versatility is essential for meeting modern industrial demands. This guide provides an in-depth look at copper strip production, types, benefits, and factors to consider when choosing a copper strip manufacturer. If you’re seeking to buy copper strips for electrical, industrial, or architectural purposes, read on to learn more about copper strip manufacturing, copper strip grades, and best practices for procurement.

What Is Copper Strip and How Is It Made?

A copper strip is a flat, elongated piece of copper metal, available in varying thicknesses and widths, that offers outstanding electrical conductivity, thermal conductivity, malleability, and corrosion resistance. It is frequently used in electrical wiring, power distribution, transformer windings, bus bars, switchgear, electronics, and countless other applications. The production of copper strip begins with the extraction of copper ore, most commonly oxide or sulfide ores containing between 0.5% and 2.0% copper. Currently, sulfide ores account for about 80% of global copper production. The refining and fabrication process involves several steps designed to maximize purity, mechanical properties, and product performance.

Key Stages in Copper Strip Manufacturing

Curious about “How are copper strips manufactured?” or “What are the main steps in copper strip production?” Here is a detailed, step-by-step look at the copper strip manufacturing process:

Stage 1: Melting Down Copper

Modern copper strip production starts with the melting of copper in electric induction furnaces. These industrial furnaces can precisely regulate the high melting point of copper (1083°C or 1981°F), ensuring the metal melts evenly and safely. Induction furnaces are preferred for their energy efficiency, process control, and enhanced safety compared to traditional foundries. Depending on the application, pure copper or copper alloys (formed by adding materials like zinc to produce brass or other copper alloys) are melted at this stage. The quality of the melt has a significant impact on the resulting copper strip’s electrical and mechanical performance.

Stage 2: Laboratory Testing and Quality Assurance

After melting, samples from each copper batch are sent to a laboratory for rigorous testing. Analytical techniques are used to verify the chemical composition, purity, and compliance with customer specifications and international standards (such as ASTM B152 for copper sheet, strip, plate, and rolled bar). This stage is critical to guarantee the copper strip’s electrical conductivity, tensile strength, ductility, and resistance to corrosion.

Stage 3: Casting and Cutting

Once approved, molten copper is cast into slabs or billets. These are then formed into copper strips by hot or cold rolling, depending on the desired thickness and finish. The entire copper strip (sometimes called copper tape or copper ribbon in narrower widths) is placed on precision cutting tables. Cutting wheel saws and shearing machines are used to achieve the required dimensions. Surface finishing equipment, such as copper strip surface washing machines, remove oxides and smooth out surface irregularities. This step ensures a flat, smooth surface, which is especially important for applications in electronics and electrical power systems.

Stage 4: Hot Rolling

The copper strip is then reheated to about 1,000°C (1,832°F) and passed through rolling mills to achieve uniform thickness and improved grain structure. Hot rolling enhances the strip’s workability and mechanical properties, enabling manufacturers to produce copper strips in a wide range of thicknesses—from ultra-thin foils (as thin as 0.01 mm) to heavy-gauge strips (up to 60 mm).

Stage 5: Washing and Surface Treatment

After hot rolling, the strip may still retain surface oxides or impurities. The copper is subjected to further heat treatment in a sealing furnace and then washed in acid solutions. This acid wash removes discoloration (such as red plaques) and remaining oxides, leaving the copper strip with a clean, lustrous finish. Regular monitoring and adjustment of acid concentration are necessary to ensure effective cleaning. Surface cleaning is essential for applications where electrical conductivity and solderability are paramount, such as printed circuit boards (PCBs) and electrical contacts.

Stage 6: Cold Rolling and Final Processing

In the final stages, the copper strip is cold rolled to its final thickness and annealed (heat treated) to achieve the specified mechanical properties. The material may also be slit into narrower widths or coiled for shipping. At this point, manufacturers may apply coatings, lamination, or insulation (for example, to produce enameled copper strips), depending on the intended use.

Copper Strip Types, Grades, and Customizations

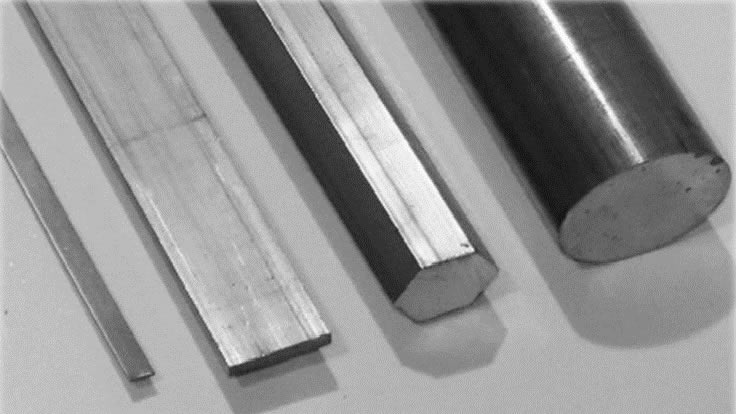

What are the different types of copper strips available? Copper strips can be classified by purity, surface finish, mechanical strength, and the presence of coatings or insulation. The two most common varieties are:

Bare Copper Strip

Bare copper strip is produced from high-conductivity copper (often C11000 or ETP copper) and is supplied without any surface insulation or coating. These strips offer precise dimensional tolerances, crack-free bends, and excellent corrosion resistance. Widths typically range from 6 mm (0.23622”) up to 359 mm (14.1339”), with thicknesses from 0.01 mm to 60 mm. Bare copper strips are widely used in:

- Automatic machinery for enhanced production efficiency

- Electrical conductors, bus bars, and switch terminals

- Transformer windings and generator components

- Appliance manufacturing and industrial equipment

- Grounding systems, especially in environments with high soil salinity

- Architectural applications, such as flashing, roofing, and decorative elements

Enameled Copper Strips

Enameled copper strips, sometimes called insulated copper strips or magnet wire, feature a protective enamel coating that provides electrical insulation, heat resistance, and improved durability. These strips are ideal for:

- Electrical insulation in transformers, motors, and generators

- High-voltage electric motor windings and stators

- Switchgears and power distribution units

- Specialized transformers for oil fields and industrial facilities

- Binding and interconnection of electrical components

The enamel insulation prevents short circuits, improves winding density, and allows for reliable performance in demanding environments. Enameled copper strips are available in various temperature classes, thicknesses, and color codes.

Tinned and Coated Copper Strips

Some copper strip suppliers offer tinned copper strips, in which a thin layer of tin is deposited on the copper surface. Tin plating enhances corrosion resistance, solderability, and long-term reliability, making tinned copper strips popular in marine, automotive, solar, and telecommunication applications. Other coatings, such as nickel or silver, may be applied for specialized uses requiring extreme conductivity or oxidation resistance.

Custom Copper Strip Solutions

Are you looking for custom copper strip fabrication? Leading manufacturers offer tailored solutions, including:

- Custom widths, thicknesses, and coil sizes

- Punched or slotted copper strips for bus bars and connectors

- Laminated or foil-backed copper strips for EMI/RFI shielding

- Precision-cut copper tapes for electronics and PCB manufacturing

- Insulated or multistrand copper strips for electrical assemblies

Consulting with a reputable copper strip supplier ensures your project receives materials that meet exact specifications and industry standards.

Applications and Industries Using Copper Strips

What are copper strips used for? Due to their unmatched electrical and thermal properties, copper strips are essential to a wide spectrum of industries and use cases:

- Electrical Power Distribution: Copper strips are the backbone of bus bars, switchgear, transformers, and power electronics, ensuring efficient and reliable energy transfer.

- Electronics Manufacturing: Used in printed circuit boards (PCB), connectors, and EMI/RFI shielding to provide signal integrity and minimize losses.

- Renewable Energy: Employed in photovoltaic solar panels, wind turbines, and battery storage systems for their high conductivity and durability.

- Automotive and Transportation: Utilized in electric vehicle (EV) battery connections, wiring harnesses, and grounding applications.

- Industrial Equipment: Copper strips are used in motors, generators, relays, and various types of heavy machinery.

- Construction and Architecture: Applied in roofing, facades, flashing, and interior design for their corrosion resistance and aesthetic appeal.

- Telecommunications: Used in grounding systems, signal transmission, and cable shielding for superior reliability.

- Medical Devices: Integrated into diagnostic equipment and imaging technology for their purity and conductivity.

Why Choose Copper Strip Over Alternative Materials?

When comparing copper strips to alternatives such as aluminum strip or steel strip, copper consistently outperforms in key areas:

- Superior Conductivity: Copper offers the highest electrical conductivity among non-precious metals, making it indispensable for electrical and electronic applications.

- Corrosion Resistance: Copper naturally forms a protective oxide layer, resisting corrosion in harsh environments.

- Malleability and Formability: Copper strips can be easily bent, shaped, and joined, supporting a wide range of fabrication needs.

- Thermal Conductivity: Copper’s excellent thermal properties make it ideal for heat exchangers, radiators, and cooling systems.

- Longevity and Reliability: Copper strips have a long service life and require minimal maintenance, reducing total cost of ownership.

- Recyclability: Copper is 100% recyclable without loss of performance, supporting sustainability and circular economy initiatives.

Benefits of Copper Strips in Modern Industry

How do copper strips benefit my application? Key advantages include:

- Minimal maintenance requirements after installation, lowering ongoing costs

- Unmatched performance in extreme temperatures, humidity, and corrosive environments

- Excellent electrical conductivity, supporting efficient energy transfer

- High mechanical strength and corrosion resistance compared to alternative metals

- Versatility in fabrication, enabling custom shapes, sizes, and assemblies

- Compliance with global standards and certifications (e.g., RoHS, REACH, ASTM, IEC)

- Wide availability and compatibility with automated production lines

How to Select a Copper Strip Supplier or Manufacturer

When sourcing copper strips for your project, what should you consider? Here’s a practical checklist to help you compare copper strip suppliers and manufacturers:

- Product Range: Does the supplier offer a broad selection of copper strip sizes, grades, and finishes (bare, enameled, tinned, custom)?

- Quality Control: Are their products tested for chemical composition, mechanical properties, and compliance with international standards?

- Customization Options: Can they provide tailored solutions for unique dimensions, coatings, or fabrications?

- Certifications: Do they hold relevant certifications such as ISO 9001, ASTM, or RoHS/REACH compliance?

- Production Capacity: Are they capable of meeting your volume requirements and delivery timelines?

- Technical Support: Do they offer engineering guidance, material selection advice, and after-sales support?

- Global Logistics: Can they ship reliably to your location, and do they offer packaging options to protect sensitive copper products?

To ensure the best results when purchasing copper strips, compare at least 4 or 5 companies using our curated list of copper strip manufacturers. Each business profile highlights their expertise, capabilities, and areas of specialization. Use the contact form provided to request detailed information, technical datasheets, or a quote tailored to your project.

Need help evaluating copper strip suppliers? Ask yourself:

- What are the key performance metrics required for my application (conductivity, thickness, tolerance)?

- Does the supplier offer value-added services such as cutting, punching, or lamination?

- Can they provide samples or prototypes for testing prior to large-scale orders?

- Are their products competitively priced while maintaining high quality standards?

- Can I easily reach their technical support team for assistance with design or troubleshooting?

Frequently Asked Questions About Copper Strip Products

What’s the difference between copper strip and copper sheet?

Copper strip generally refers to long, narrow, and thin pieces of copper—often supplied in coils or ribbons—while copper sheet is wider and thicker, typically supplied flat. Both are made from high-conductivity copper, but their dimensions and intended uses differ. Strips are ideal for electrical conductors and bus bars, while sheets are used in roofing, cladding, and industrial fabrication.

Can copper strips be recycled?

Yes, copper strips are fully recyclable. Scrap copper strip can be melted down and reprocessed into new products without losing its desirable properties. This supports sustainable manufacturing and reduces environmental impact.

How do I choose the right copper strip for my application?

Consider factors like required conductivity, mechanical strength, thickness, width, surface finish, and whether insulation or coating is needed. Consult with your supplier or manufacturer for material selection and custom options based on your specific use case.

Are there industry standards for copper strips?

Yes. Common standards include ASTM B152/B152M for copper sheet, strip, plate, and rolled bar, as well as international equivalents such as IEC and JIS. Always request documentation and certification when purchasing copper strip products.

What finishes and coatings are available?

Copper strips can be delivered bare, tinned, enameled, or with specialized coatings (such as nickel or silver) depending on the application. Surface finish options include bright, matte, or textured. Some suppliers offer laminated or adhesive-backed strips for easy installation.

How can I get a quote or place an order?

Visit our list of copper strip manufacturers, review their capabilities, and use the provided RFQ (Request for Quote) form to contact multiple suppliers at once. Be sure to specify your required dimensions, material grade, finish, and any special requirements to receive accurate pricing and lead time information.

Conclusion: Maximizing Value with the Right Copper Strip Supplier

Choosing the optimal copper strip for your needs depends on understanding material properties, manufacturing processes, and supplier capabilities. Whether you’re seeking bare copper strips for power distribution, enameled copper strips for transformer windings, or custom copper foil for electronics, a trusted copper strip manufacturer can deliver the quality and performance your project demands. Compare multiple suppliers, request samples or technical datasheets, and leverage expert support to ensure your copper strip solution meets all technical, commercial, and regulatory requirements.

Ready to source copper strips? Explore our directory of copper strip suppliers or request a quote to get started on your next project.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services