To improve a metal’s qualities, it is mixed with another metal or other non-metal elements to form an alloy. Beryllium copper (BeCu) is a metal alloy of copper which is achieved by adding beryllium (ranging from 0.5% to 3%). Typically beryllium is added to increase copper’s strength. The specific grade of beryllium copper depends on the ratio of beryllium to copper and each grade has other beneficial characteristics. Read More…

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

With over 25 years of metallurgy experience we guarantee we can produce exactly what you are looking for. We offer fast delivery and a multitude of beryllium copper sizes. Our highly knowledge staff takes great pride in creating these outstanding copper alloys. We have a reputation of manufacturing the best copper fabrications. Our company has risen in the standard in copper processing. Contact...

At Source 21, Inc., we take pride in offering top-notch copper products to meet a wide range of industrial and commercial needs. When it comes to copper, we've established ourselves as a reliable provider known for quality, accessibility, and customer satisfaction. Our extensive array of copper products is designed to cater to your diverse requirements while ensuring uncompromised excellence.

Schorr Metals is a complete metal service center and your best source for copper and brass extrusions, sheets and more with customized fabrication services, cutting, welding and rolling services. Combining our inventory of copper, brass, steel and other metals with our exceptional customer service and capabilities, the answer is clear - Schorr Metals is your choice for quality, service and value.

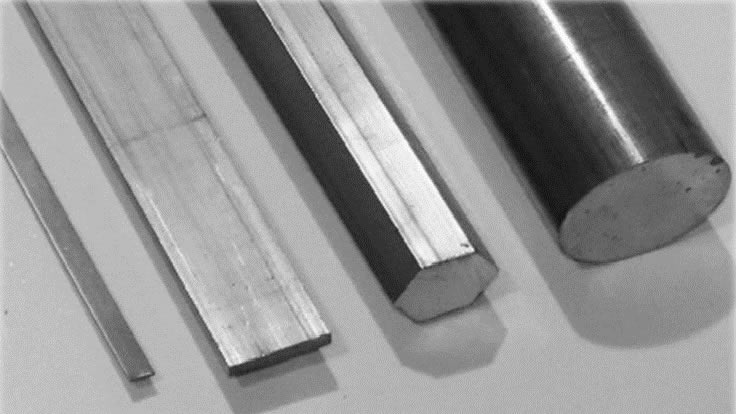

We are committed to our customers. Our engineers manufacture copper products that exceed regulatory standards. Our products are the best quality and adhere to a multitude of rigorous physical testing to ensure the reliability of our copper. You can rest assured that you are receiving the best copper. From tubes, rounds, hollows, squares, hexagons and more, we have it all! Please visit our website ...

More Beryllium Copper Suppliers

The distinction between these grades is made based on their conductivity and strength. As one of the greatest strength copper-based alloys, this alloy is used in all industrial sectors. In addition to their high strength, different grades of beryllium copper exhibit other qualities, such as superior conductivity and non-magneticity, that make them appropriate for a variety of industrial applications.

Traditionally, machine parts and tools have been made of this alloy. Today, it may now be used in electronics and other fields because of improved casting, enhanced machining, and other developments that have made this alloy suitable for various applications.

Properties of Beryllium Copper

Beryllium copper and its assortment of alloys exhibit many beneficial characteristics including:

- It provides superior thermal and electrical conductivity.

- Beryllium copper’s high ductility and outstanding formability are essential with regards to machining, forming, and metalworking processes.

- It is non-magnetic.

- Beryllium copper is suitable for use in hazardous or combustible conditions since it is non-sparking. As a result, the mining, petroleum, and oil-drilling industries now employ it frequently.

- It is more durable than the majority of copper alloys and resists wear and galling (another form of wear caused by sliding surfaces).

- It retains its beneficial characteristics in very high or very low temperatures.

- This material provides greater corrosion/oxidation resistance than steel.

- It is suitable for activities involving precipitation-hardening used to help create even-stronger super alloys.

- Beryllium copper has a high tensile strength: Beryllium copper is the strongest copper alloy, with a maximum load-bearing capacity of around 200,000 pounds per square inch. This strength can be further increased through precipitation hardening (also known as age hardening).

Types of Beryllium-Copper Alloys

The amount of beryllium, along with other alloying elements used, and the heat treatment procedures used by the manufacturer all have a significant impact on the physical qualities of a specific beryllium-copper alloy. Based on their composition and the intrinsic physical characteristics they display, beryllium copper alloys are categorized into two types: high-conductive beryllium-copper alloys or high-strength copper alloys made of beryllium. We discuss each of these categories below.

High-Conductive Beryllium-Copper Alloys

These alloys have a lower beryllium concentration, ranging from 0.2% to 0.7%, as well as minute amounts of cobalt and nickel. These alloys have a high degree of electrical and thermal conductivity, as their name suggests.

- C17510 or Alloy 3

It is utilized in applications that have a need for moderate strength and resistance to thermal fatigue. C17510 contains 1.4% to 2.2% nickel and 0.26% to 0.6% beryllium.

- C17500 or Alloy 10

This alloy has a beryllium content of 0.4% to 0.27% percent and a higher cobalt content of 2.4% to 2.7%. The higher cobalt marginally reduces the thermal conductivity and melting point of C17500. The qualities of C17500 and C17510 include high electrical and thermal conductivity, strength, and hardness as their defining characteristics.

High-Strength Copper Alloys Made of Beryllium

For heavier-duty applications, the beryllium content ranges from 1.6% to 2.05% in high-strength copper alloys. The increased level of beryllium is what provides these beryllium alloys their extraordinary strength. Examples of high strength beryllium copper alloys include:

- Alloy 25 or C17200

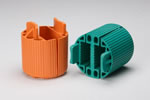

The strongest and hardest of the beryllium-copper alloys, C17200 or Alloy 25, possesses a hardness and strength comparable to steel. It has a tensile strength that can reach 200 ksi and includes 2% beryllium. C17200 lowers the temperature of the mold when introduced into a plastic mold, negating the requirement for cooling water.

- Alloy M25 or C17300

C17300 shares many of the same characteristics as C17200. Alloy M25, also referred to as "leaded beryllium copper," additionally contains a minute portion of lead (ranging between .2% and .6%), which makes it machinable for use in manufacturing, particularly in the fabrication of precision parts.

Applications

As previously discussed, beryllium copper has numerous characteristics beneficial for a variety of applications. Some specific areas where beryllium copper may be found include:

- As electrodes used in resistance welding and spot welding

- In components of vehicles and communication satellites

- As springs & spring wires

- In nozzles for injection machines

- In metal die casting

- As plunger tips

- In molding inserts and in plastic injection

Choosing the Proper Beryllium Copper Supplier

To make sure you have the most beneficial outcome when purchasing Beryllium Copper from a Beryllium Copper Supplier, it is important to compare at least 5 or 6 Companies using our list of Beryllium Copper suppliers. Each Beryllium Copper Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Beryllium Copper business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Beryllium Copper businesses with the same quote.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services