The second most prevalent element in bronze is tin, which is also variable commonly composing between 12% and 40% of the alloy. Read More…

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

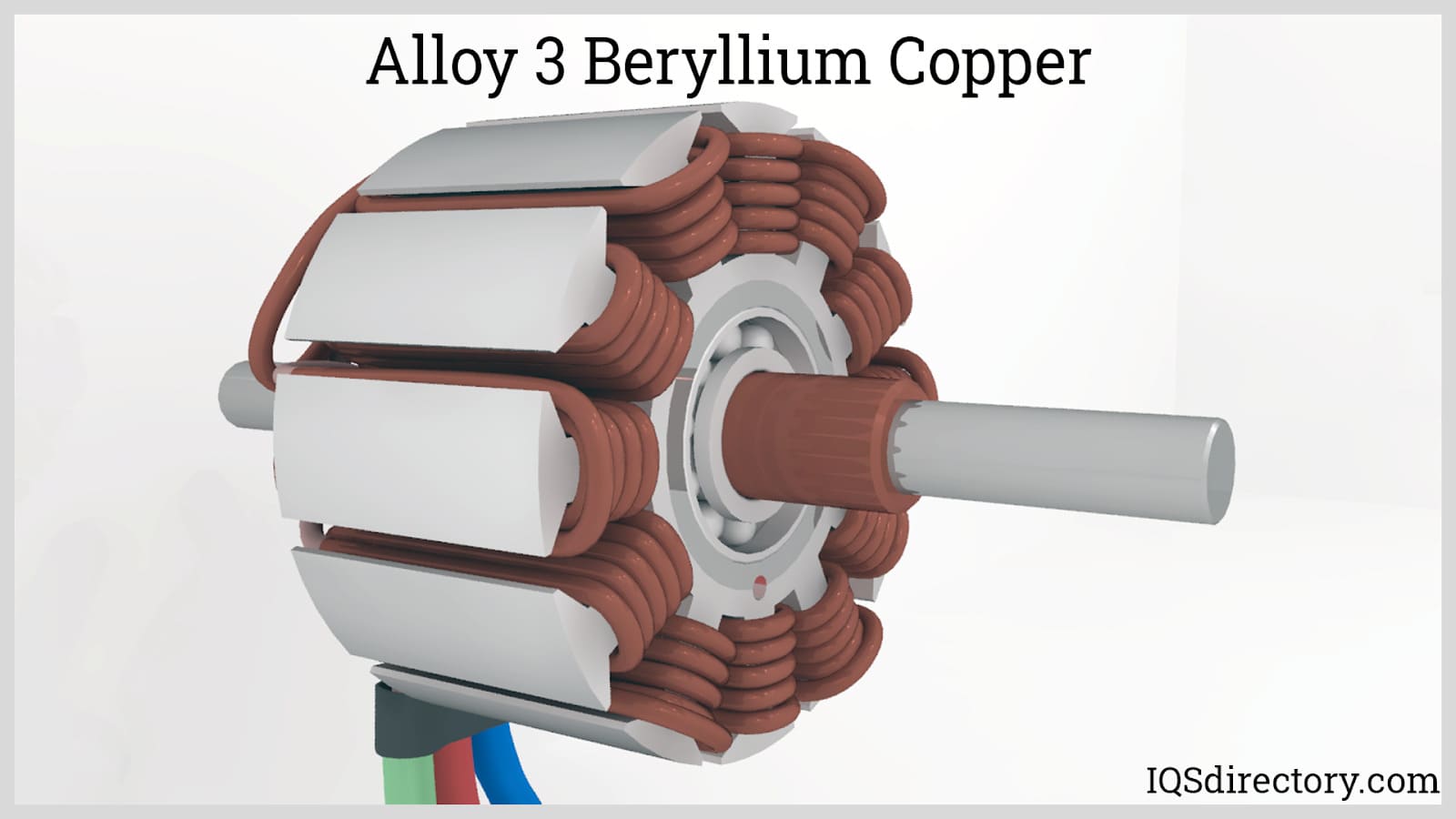

With over 25 years of metallurgy experience we guarantee we can produce exactly what you are looking for. We offer fast delivery and a multitude of beryllium copper sizes. Our highly knowledge staff takes great pride in creating these outstanding copper alloys. We have a reputation of manufacturing the best copper fabrications. Our company has risen in the standard in copper processing. Contact...

At Source 21, Inc., we take pride in offering top-notch copper products to meet a wide range of industrial and commercial needs. When it comes to copper, we've established ourselves as a reliable provider known for quality, accessibility, and customer satisfaction. Our extensive array of copper products is designed to cater to your diverse requirements while ensuring uncompromised excellence.

Schorr Metals is a complete metal service center and your best source for copper and brass extrusions, sheets and more with customized fabrication services, cutting, welding and rolling services. Combining our inventory of copper, brass, steel and other metals with our exceptional customer service and capabilities, the answer is clear - Schorr Metals is your choice for quality, service and value.

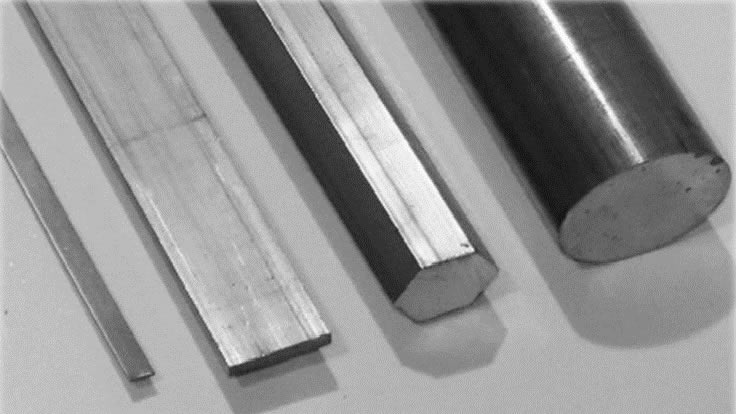

We are committed to our customers. Our engineers manufacture copper products that exceed regulatory standards. Our products are the best quality and adhere to a multitude of rigorous physical testing to ensure the reliability of our copper. You can rest assured that you are receiving the best copper. From tubes, rounds, hollows, squares, hexagons and more, we have it all! Please visit our website ...

More Bronze Suppliers

The mixture of tin and copper results in bronze, an alloy that is less brittle than tin and iron, but harder and more durable than pure copper. Additionally, bronze is more readily melted and easier to cast or work. Additional elements such as manganese, lead, zinc, silver, phosphorous, arsenic and more may also be added to enhance specific features of special-purpose bronzes. These and other less complex varieties of bronze are available to suit a wide range of industrial applications. Aluminum bronze, which offers high strength and resistance to corrosion, is used to make bearings, valves, and machine components.

Silicon bronze is used for telegraph wires and chemical containers, whereas phosphor bronze is used to make springs. Leaded bronze, a very strong type of bronze, is used in heavy-duty bushings and bearings. Bronze can also be used to cast bells. Other items that contain bronze include gunmetal, coins, castings, engravings, forgings, steam and water fittings, electrical connectors, gears, valves, and more. In general, industrial applications for bronze also take advantage of its good thermal and electrical conductivity, minimal metal-on-metal friction and non-sparking properties.

As aforementioned, bronze is more easily formed than either pure copper or tin. Though slightly less malleable than pure copper, a number of manufacturing methods are commonly employed in the processing of bronze parts and components. Before machining, however, bronze production begins much like that of any alloyed metal with the combination of copper, tin and any additional additives. These elements, often in the more of metal scrap, are weighed and appropriate amounts transported into a furnace, commonly electric. At this point the mixture is heated to temperatures in excess of 1700°F (950°C). Such temperatures allow for the homogenization of the molten materials.

Once this occurs the metal is poured or cast into stock shapes and allowed to cool before further processing. These billets and ingots are then formed as needed into bronze bars, plates, sheets, foils, strips, rods and other stock shapes via hot or cold rolling, extrusion, drawing, cutting or more. With a wide range to choose from, manufacturers select the stock shape most easily incorporated into the design of the final product which may then undergo several secondary processes. Though a lacquer may need to be applied to prevent the formation of patina, the natural dark amber hue of bronze is desirable in many applications and finishing is not often needed even for aesthetic components.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services