Brass, also known as Copper Alloy 356, is used widely due to its versatility. It comprises approximately 62% copper, 36% zinc, and trace amounts of lead. Brass, unlike other metals, has a rich brown hue that makes it an ideal material for decorations. It’s common in air, gas, plumbing, and hobby applications. Brass is used in radiator components, ammunition casings, and various hardware. It is not as resistant to corrosion as stainless steel, but is softer and easier to fabricate. Brass is also nonmagnetic, making it an important component in the manufacture of clocks and electrical parts for circuits. Read More…

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

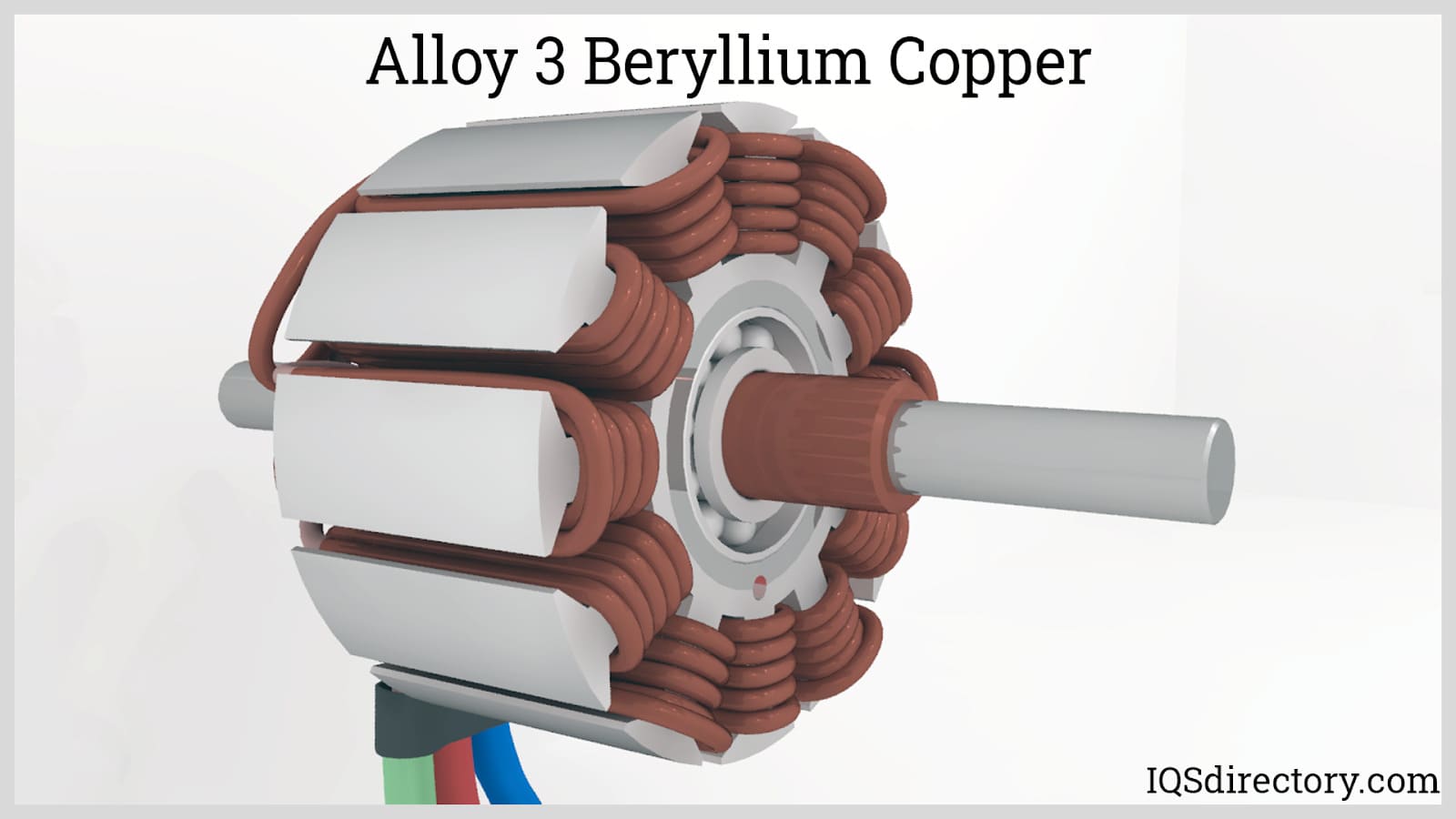

With over 25 years of metallurgy experience we guarantee we can produce exactly what you are looking for. We offer fast delivery and a multitude of beryllium copper sizes. Our highly knowledge staff takes great pride in creating these outstanding copper alloys. We have a reputation of manufacturing the best copper fabrications. Our company has risen in the standard in copper processing. Contact...

At Source 21, Inc., we take pride in offering top-notch copper products to meet a wide range of industrial and commercial needs. When it comes to copper, we've established ourselves as a reliable provider known for quality, accessibility, and customer satisfaction. Our extensive array of copper products is designed to cater to your diverse requirements while ensuring uncompromised excellence.

Schorr Metals is a complete metal service center and your best source for copper and brass extrusions, sheets and more with customized fabrication services, cutting, welding and rolling services. Combining our inventory of copper, brass, steel and other metals with our exceptional customer service and capabilities, the answer is clear - Schorr Metals is your choice for quality, service and value.

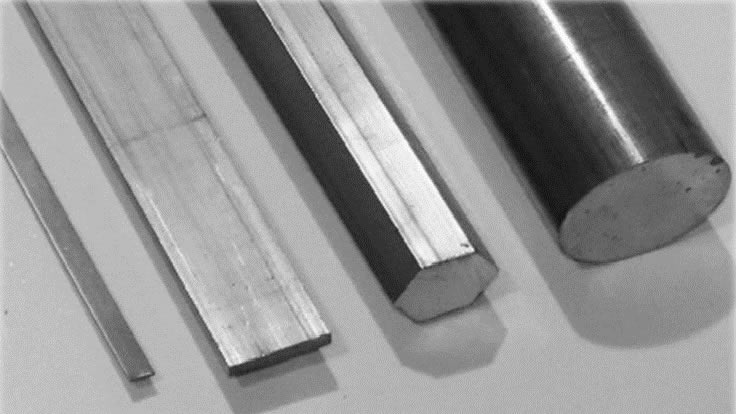

We are committed to our customers. Our engineers manufacture copper products that exceed regulatory standards. Our products are the best quality and adhere to a multitude of rigorous physical testing to ensure the reliability of our copper. You can rest assured that you are receiving the best copper. From tubes, rounds, hollows, squares, hexagons and more, we have it all! Please visit our website ...

More Brass Tubing Suppliers

Types Of Brass Tubing

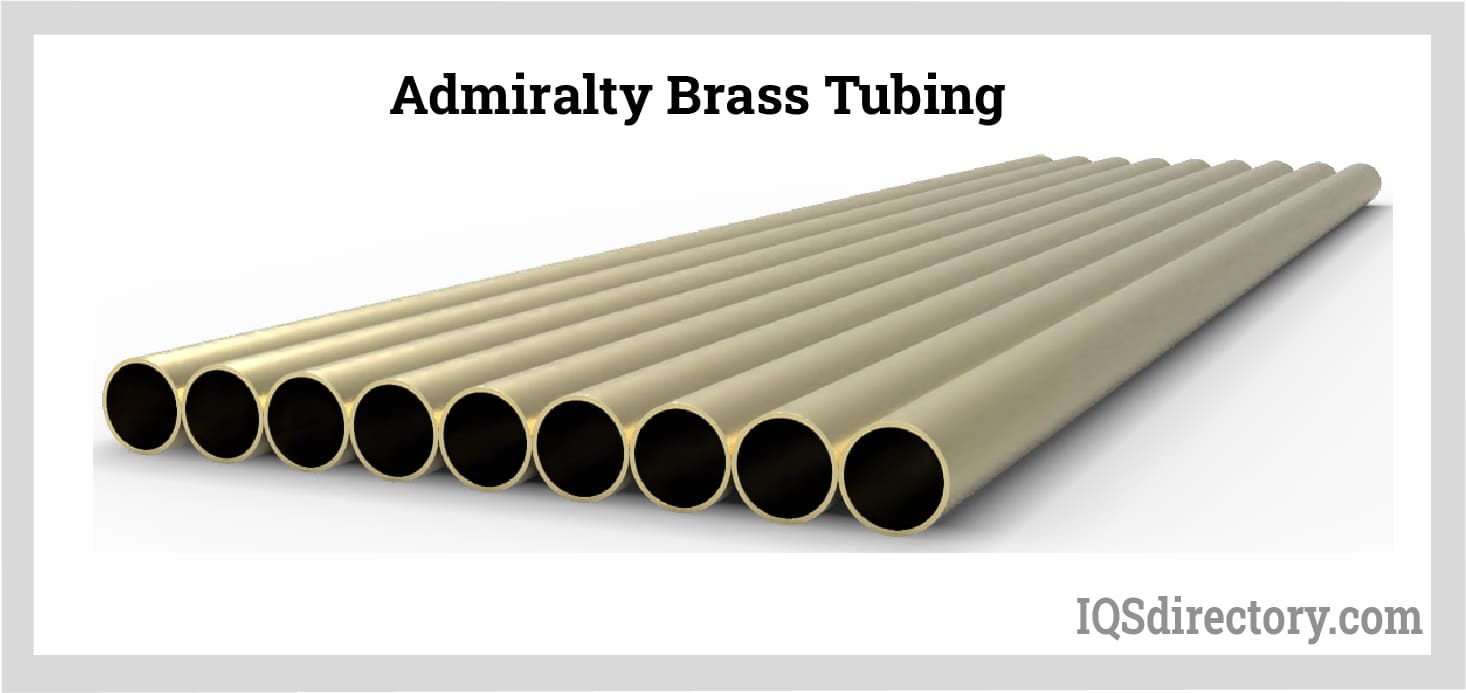

- Admiralty Brass Tubing: Admiralty brass is classified as a copper-zinc alloy, with a typical copper-to-zinc ratio of 70% to 30%. This brass type's important additional component is tin, which makes the alloy highly corrosion-resistant. It has a small amount of arsenic used to combat dezincification. This brass tubing is best suited for shipbuilding, heat exchange equipment, oil well pumps, condensers, distillers, and other heavy-duty mechanical applications.

- Commercial Brass Tubing: "Commercial brass" is a broad category, but brass alloys in this classification contain 65% copper and 37% zinc. Commercial brass tubing has excellent cold working characteristics and is reasonably priced. The best use for commercial brass is general engineering, agricultural equipment, and sanitation components.

- Aluminium Brass Tubing: Aluminum brass alloy has aluminum% to increase corrosion resistance. Because of its composition, aluminum brass is best suited for cooling water quickly, so it’s used in land and marine power plants. The best applications for this copper-zinc alloy are heat exchangers, salt and freshwater processing equipment, offshore platforms, and desalination plants.

Cleaning Brass Tubes

One of the reasons for using brass tubing over others indoors is its ornamental properties. It should be cleaned with a weak acid such as vinegar or citric acid to remove ditty and debris. Conventional household cleaners should be avoided since they contain high ammonia, and soft brass polishing compounds are best for this purpose.

Applications Of Brass Tubing

- Heat exchange systems in buildings, ships, oil wells pumps

- Agricultural fittings and accessories, water processing heat exchangers, desalination plants

- Brass, when available in flat sheets, can be used for engraving.

- Brass tubing can be used in various interior design and fabrication projects, like designing light fixtures.

- Brass tubing is used widely to manufacture musical instruments such as French horns, trumpets, and trombones.

Advantages Of Brass Tubing

As an alloy, brass overcomes the limitations of copper or zinc alone. It is ductile enough to be molded into any desired shape. Brass is very corrosion-resistant and does not tarnish ore rust over time. Because of brass’ high friction coefficient, it can be used on bearing and other moving parts.

Disadvantages Of Brass Tubing

Brass can be sensitive to environmental ph levels, whether acidic or alkaline, and over-exposure can result in tarnishing. It is slightly toxic, It erodes over time when exposed to moisture and oxygen. Brass can be expensive.

Conclusion

Brass is a copper and zinc alloy that overcomes some of the limitations of pure copper and pure zinc. It is strong, durable, and malleable and, when cared for properly, does not rust, corrode, or tarnish. The copper-to-zinc ratios differentiate the type of brass and hence determine its most suited applications. Due to its versatility, the choice of the specific type to use can be best advised by the supplier.

Choosing the Correct Brass Tubing Manufacturer

To make sure you have the most constructive outcome when purchasing Brass Tubing from a Brass Tubing Manufacturer, it is important to compare at least 6 Suppliers using our list of Brass Tubing manufacturers. Each Brass Tubing Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Brass Tubing business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Brass Tubing companies with the same message.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services