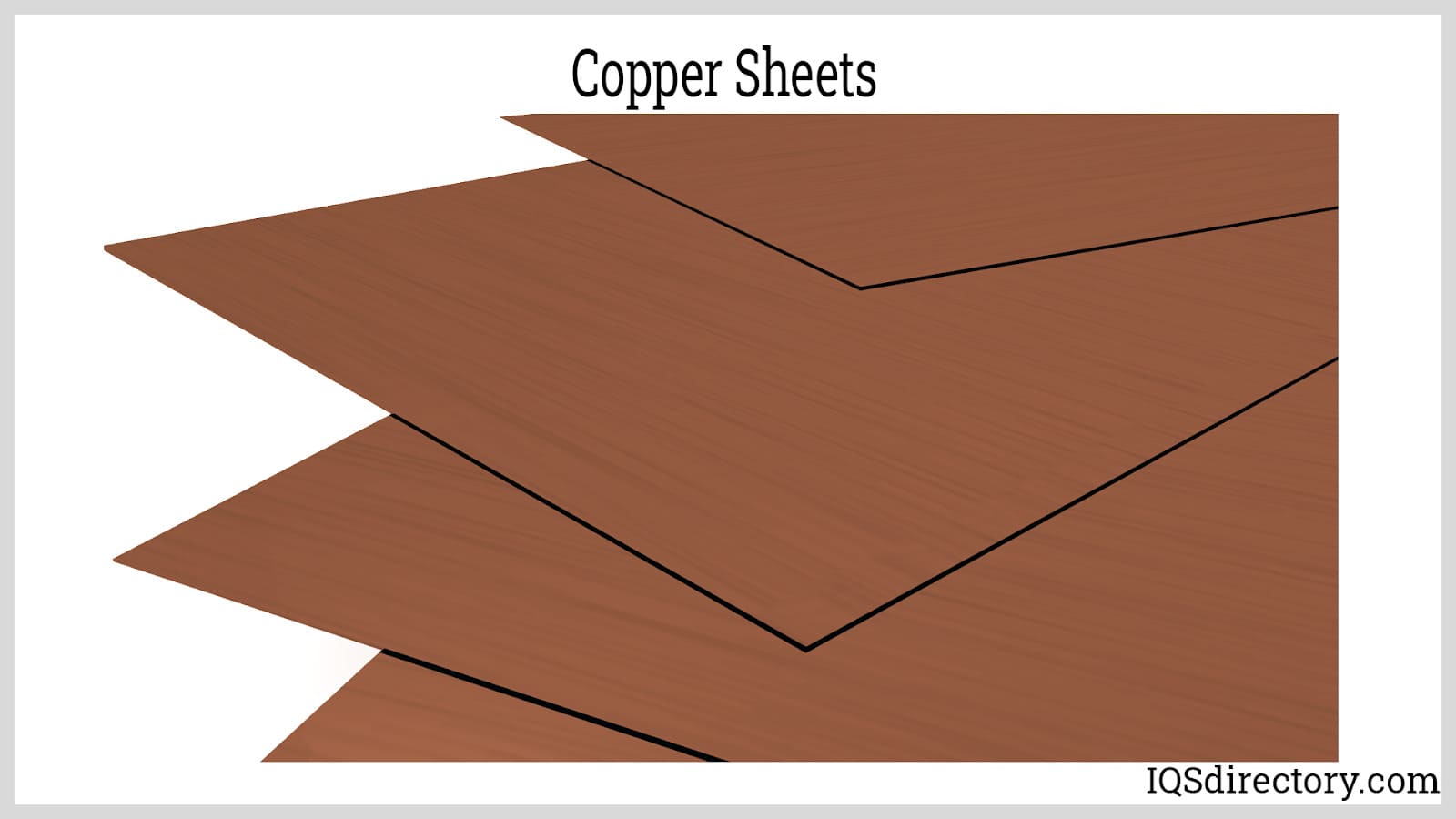

Copper is one of the most abundant and useful metals available. Copper exhibits excellent electrical and thermal conductivity, corrosion resistance, and malleability. Copper is formed into sheet materials which are then used to create the various copper products and items we rely on every day. Read More…

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

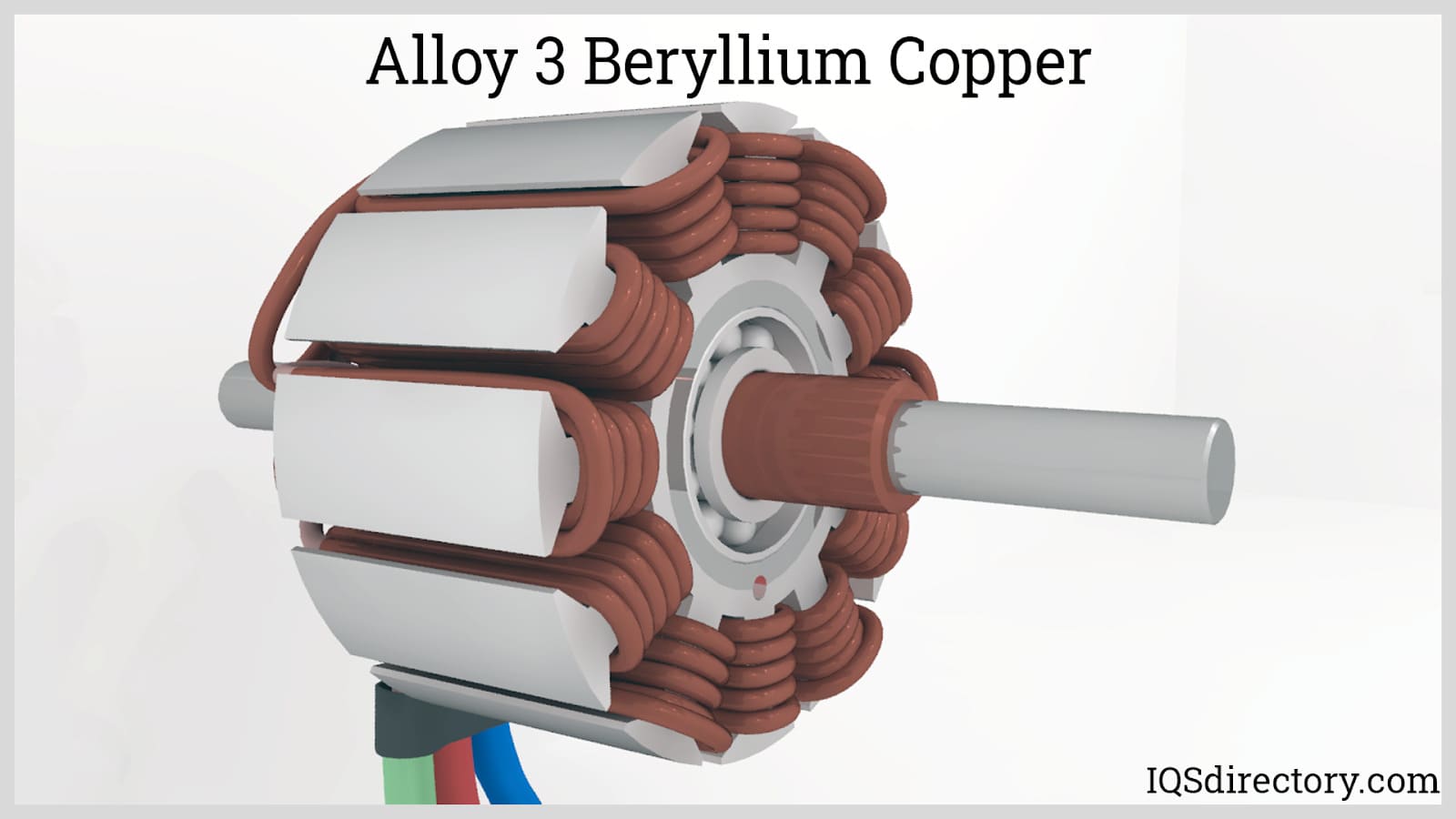

With over 25 years of metallurgy experience we guarantee we can produce exactly what you are looking for. We offer fast delivery and a multitude of beryllium copper sizes. Our highly knowledge staff takes great pride in creating these outstanding copper alloys. We have a reputation of manufacturing the best copper fabrications. Our company has risen in the standard in copper processing. Contact...

At Source 21, Inc., we take pride in offering top-notch copper products to meet a wide range of industrial and commercial needs. When it comes to copper, we've established ourselves as a reliable provider known for quality, accessibility, and customer satisfaction. Our extensive array of copper products is designed to cater to your diverse requirements while ensuring uncompromised excellence.

Schorr Metals is a complete metal service center and your best source for copper and brass extrusions, sheets and more with customized fabrication services, cutting, welding and rolling services. Combining our inventory of copper, brass, steel and other metals with our exceptional customer service and capabilities, the answer is clear - Schorr Metals is your choice for quality, service and value.

We are committed to our customers. Our engineers manufacture copper products that exceed regulatory standards. Our products are the best quality and adhere to a multitude of rigorous physical testing to ensure the reliability of our copper. You can rest assured that you are receiving the best copper. From tubes, rounds, hollows, squares, hexagons and more, we have it all! Please visit our website ...

More Copper Sheet Suppliers

How Copper Sheets are Manufactured

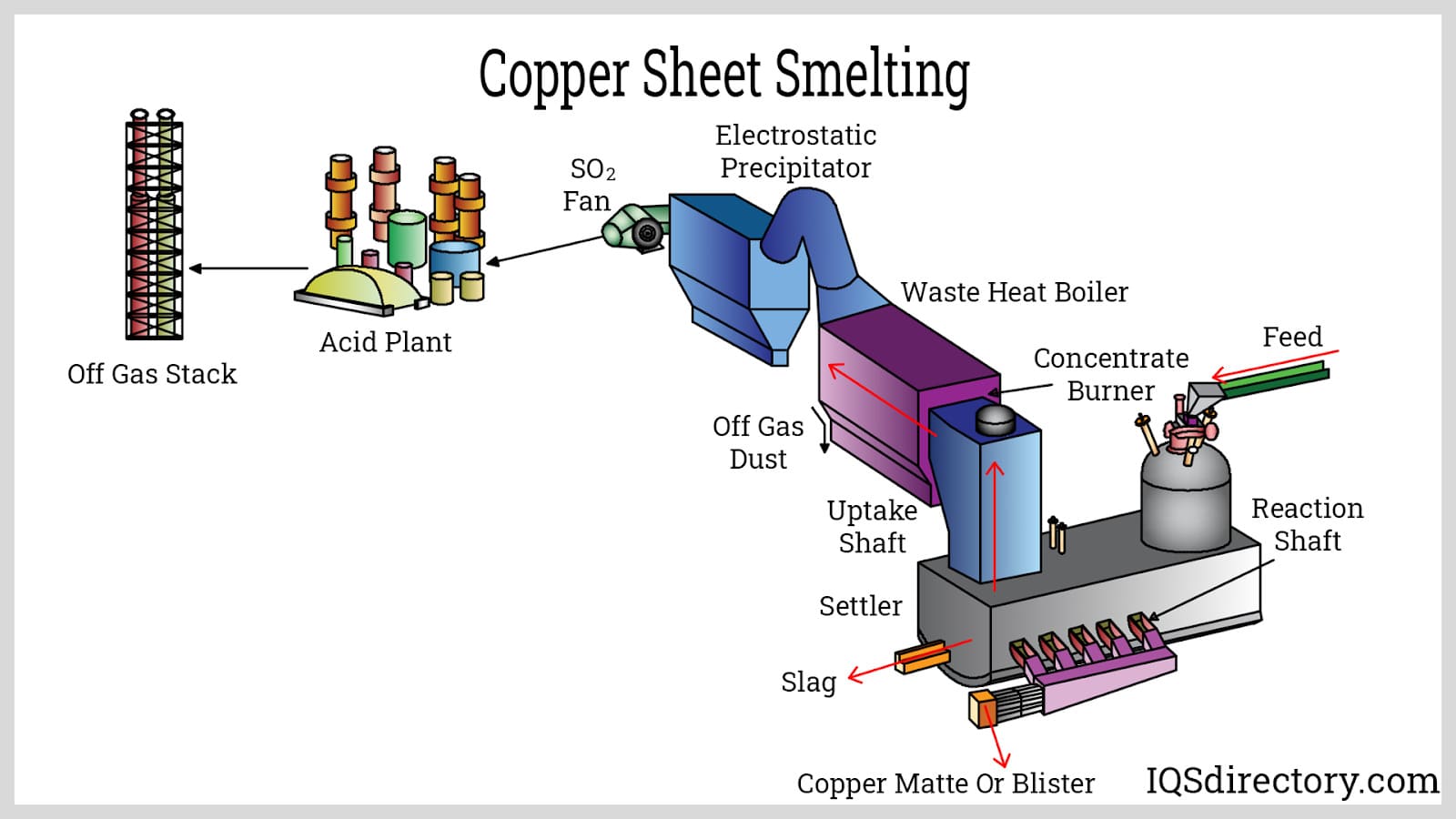

In nature, it is quite rare to find copper in its purest form. Instead, it is typically present along with other compounds in copper ores. The finest form of copper is obtained by extracting it and then purifying it using a variety of chemicals. First, numerous non-copper-containing minerals and significant amounts of mud and debris are removed to extract copper from the ore. After the waste is eliminated, the metal is concentrated using a slurry and flotation procedure. After being cleaned and concentrated, copper undergoes a smelting process.

Smelting is a process that uses a series of chemical processes to remove sulfur and iron from copper. Copper concentrate settles at the base of the furnace after the flux melt used to treat it is added and mixes with the copper in the furnace. Most other metals, including iron, become extremely concentrated and condense into slag, which is skimmed off the top. In a subsequent procedure known as the converter, the concentrated copper and other metals at the bottom of the furnace, known as matte, are purified to include over 99 percent copper by weight.

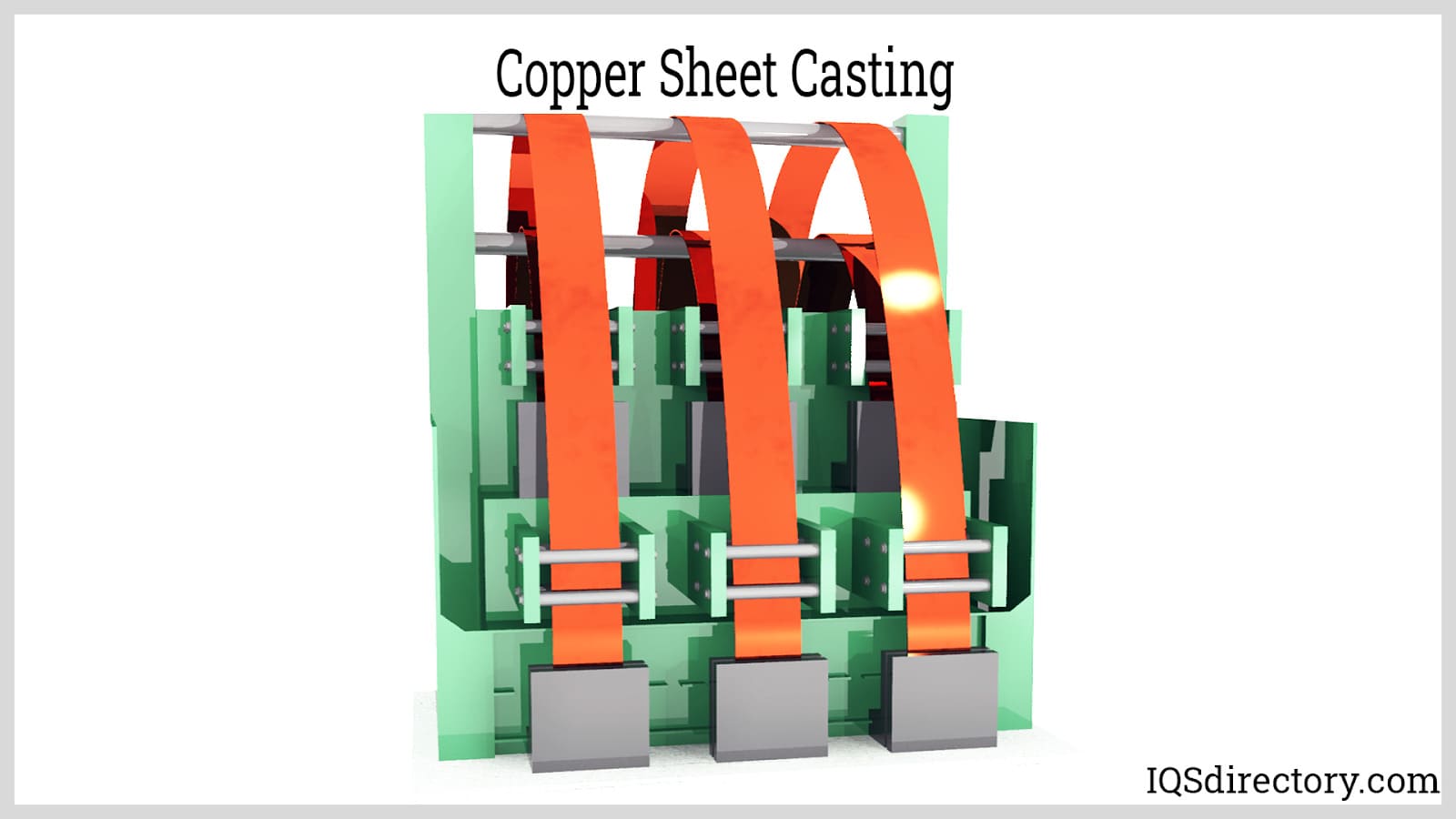

Although it is pure by weight, additional refining is necessary to remove abnormally high oxygen levels, sulfur, and other contaminants from the copper. The air oxidizes the molten metal's impurities in the refining furnace. While the copper solution is still liquid, an electrical current is passed through the tank, causing the copper solution to be drawn to a cathode and collect the metal, which is now rated to be 99.95–99.99% pure copper. After the copper cathode blocks are melted, the metal is cast into various shapes, including rods, billets, ingots, cakes, and sheets.

Types of Copper Sheets

1 Mil Copper Sheet

Only .001 inches thick, this copper foil sheet is readily shredded with the hands or formed into many shapes using paper punchers. As a result, it is frequently employed in manufacturing, electrical, and artistic applications.

1.4 Mil Copper Sheet

With a thickness of 0.0014 inches, this small copper foil sheet is roughly twice as thick as regular aluminum foil. It is easily cut and torn by hand, but it is also easily wrinkled. Similar to 1 mil copper sheet, it is used in manufacturing, electrical, and arts and crafts applications.

5 Mil Copper Sheet

This gauge of copper has a thickness of 0.005 inches and is shiny and polished. Although this foil is difficult to break by hand, scissors can cut it easily. Copper sheets with a five-mil thickness are frequently used for die-cutting, embossing, other craft projects, and other uses.

8 Mil Copper Sheet

This 0.008-inch-thick, heavy-duty copper tooling foil is used for various construction, home repair, and arts and crafts tasks. Although it may retain its shape better than 5 mil when cut with scissors, it will bend when put under strain.

10 Mil Copper Sheet

With a thickness of 0.010 inches, 10 mil copper sheets are 14 times thicker than regular aluminum foil. At this thickness, copper starts to retain its shape and hold weight. As a result, it can be cut with a pair of heavy-duty scissors or a utility knife and may be hammered or textured using those same tools.

16 Mil Copper Sheet

There are several sizes of copper sheeting with a 16 mil thickness. It is stiffer than thinner materials. Because it is a particularly robust gauge of copper sheet, it is frequently used for sculptures, jewelry, and other arts and crafts.

Advantages of Copper Sheets

- Because it doesn't rust easily, copper's low reactivity makes it ideal for pipes (such as those used in irrigation sprinklers, distillation pipelines, and fuel gas lines) and electrical cables. A green patina (film coating) of copper oxide also forms on copper’s surface when exposed to air.

- Recycled copper costs about 90% of its original cost and may be recycled without diminishing quality. As a result, it is far less expensive than extracting and processing new copper (a process that also damages the environment). Although there is a lot of copper in the planet's crust, it is a finite resource; recycling will increase copper's supply. Recycling copper is done by melting the copper down, then molding it into different forms.

Disadvantages of Copper Sheets

- The copper market is volatile since it depends significantly on overseas trade with Latin America. Therefore, copper wire is expensive.

- Copper is heavy, resulting in higher shipping costs.

- Copper wire poses a greater risk or shock than fiber optic cable due to its conductivity. Because copper is extremely susceptible to electrical interference, fiber optics (coated glass fibers) provides a clearer transmission.

Choosing the Correct Copper Sheets Company

To make sure you have the most positive outcome when purchasing Copper Sheets from a Copper Sheets Supplier, it is important to compare at least 5 or 6 Companies using our list of Copper Sheets manufacturers. Each Copper Sheets Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Copper Sheets business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Copper Sheets businesses with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services