Copper tubes are a type of piping that is commonly used in various industries due to their exceptional properties. Copper tubes are durable, long-lasting, and corrosion-resistant, which makes them an ideal choice for use in many different industries. Read More…

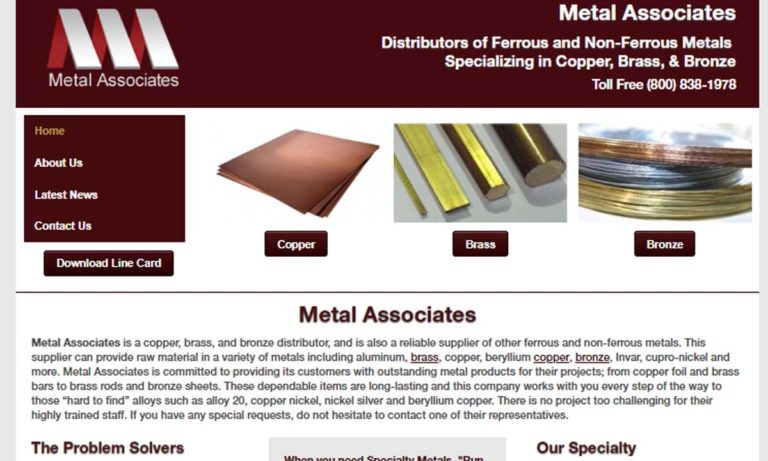

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

With over 25 years of metallurgy experience we guarantee we can produce exactly what you are looking for. We offer fast delivery and a multitude of beryllium copper sizes. Our highly knowledge staff takes great pride in creating these outstanding copper alloys. We have a reputation of manufacturing the best copper fabrications. Our company has risen in the standard in copper processing. Contact...

At Source 21, Inc., we take pride in offering top-notch copper products to meet a wide range of industrial and commercial needs. When it comes to copper, we've established ourselves as a reliable provider known for quality, accessibility, and customer satisfaction. Our extensive array of copper products is designed to cater to your diverse requirements while ensuring uncompromised excellence.

Schorr Metals is a complete metal service center and your best source for copper and brass extrusions, sheets and more with customized fabrication services, cutting, welding and rolling services. Combining our inventory of copper, brass, steel and other metals with our exceptional customer service and capabilities, the answer is clear - Schorr Metals is your choice for quality, service and value.

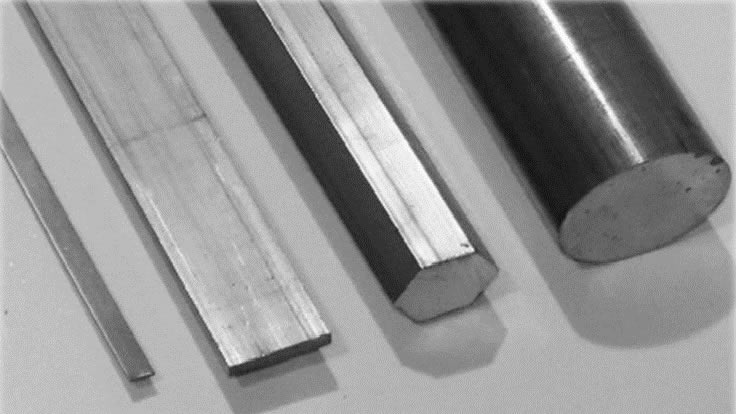

We are committed to our customers. Our engineers manufacture copper products that exceed regulatory standards. Our products are the best quality and adhere to a multitude of rigorous physical testing to ensure the reliability of our copper. You can rest assured that you are receiving the best copper. From tubes, rounds, hollows, squares, hexagons and more, we have it all! Please visit our website ...

More Copper Tube Suppliers

Why Copper Is Used to Create Tubes

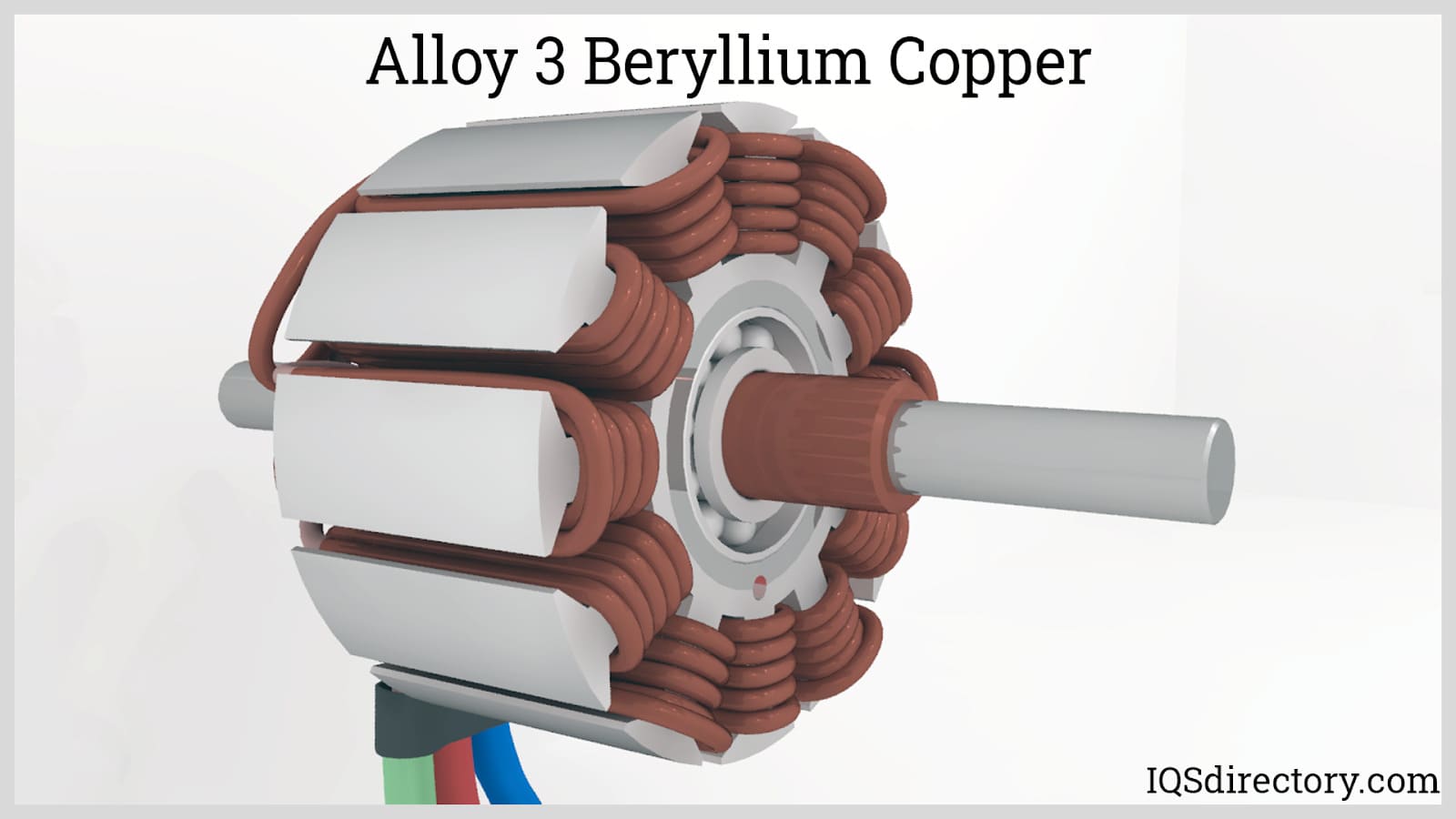

Copper is a highly conductive and ductile metal that is widely used in the production of various products. It is a soft and malleable metal that can be easily shaped and formed into different shapes and sizes. Copper is also a good conductor of heat and electricity, which makes it an ideal choice for use in electrical wiring and heat transfer applications.

Manufacturing Process of Copper Tubes

The production of copper tubes involves several stages, including raw material preparation, extrusion, drawn temper, annealing, brazing, and soldering. Raw materials are carefully selected, weighed, and melted in a furnace to create copper billets. The billets are then shaped and formed into tubes using a combination of extrusion and drawing techniques. The tubes are then annealed to increase their strength and durability before they are brazed or soldered to form the final product.

Variations in the Manufacturing Process

There are several variations in the manufacturing process of copper tubes, including seamless copper tubes, welded copper tubes, and capillary copper tubes. Seamless copper tubes are made from a single piece of copper and are often used in high-pressure applications, such as HVAC and refrigeration systems. Welded copper tubes, on the other hand, are made by welding two or more pieces of copper together and are often used in low-pressure applications, such as plumbing and heating systems. Capillary copper tubes are thin-walled tubes that are used in medical and refrigeration applications.

Considerations Regarding Copper Tubes

One of the main considerations regarding copper tubes is corrosion. Copper can corrode over time, especially in areas with high humidity or exposure to certain chemicals. This can lead to leaks and other problems. Another potential consideration is cost, as copper can be more expensive than other types of piping materials. Additionally, copper is highly conductive, which can lead to electrical problems if not installed correctly.

Benefits of Copper Tubes

Despite these potential considerations, copper tubes offer many benefits. Many of these benefits are discussed below and include:

Durability

Copper tubes are extremely durable and can withstand high levels of stress and pressure. They are resistant to damage from impact, bending, and deformation, making them ideal for use in harsh environments and applications.

Heat and Electrical Conductivity

Copperis an excellent conductor of both heat and electricity, making copper tubes ideal for applications that require efficient heat or electrical transfer. Copper's high thermal conductivity ensures that heat is rapidly transferred across the length of the tube, while its high electrical conductivity ensures that electricity can flow through the tube with minimal resistance.

Eco-Friendliness

Copper is a naturally occurring metal and is 100% recyclable. This means that copper tubes can be easily reused and repurposed, reducing the environmental impact of their production and disposal. In addition, copper is non-toxic and does not release harmful chemicals, making it a safe choice for use in various applications.

Corrosion Resistance

Copper is highly resistant to corrosion, ensuring that copper tubes last for many years without deteriorating. This makes copper tubes ideal for use in applications that are exposed to harsh environments, such as marine or industrial settings.

Malleability

Copper is highly malleable and can be easily shaped and formed into different shapes and sizes. This makes copper tubes easy to install and use in various applications, where they can be bent and shaped to fit into tight spaces.

Antimicrobial Resistance

Copper has natural antimicrobial properties, making it resistant to bacteria and other microorganisms. This makes copper tubes ideal for use in applications that require hygienic conditions, such as medical applications.

Biocompatibility

Copper is biocompatible and is widely used in medical applications, such as surgical tools and implants. Copper tubes are safe to use in contact with human tissue, making them ideal for use in medical or dental equipment.

Applications of Copper Tubes

Due to these benefits, Copper tubes have a wide range of applications, including:

Plumbing

Copper tubes are commonly used in plumbing applications to transport hot and cold water throughout buildings. They are preferred over other materials due to their excellent corrosion resistance, durability, and long lifespan. Copper tubes are also easy to install and require minimal maintenance.

HVAC and Refrigeration

Copper tubes are used in air conditioning and refrigeration systems to transfer heat and cool air. Copper's high thermal conductivity and corrosion resistance make it an ideal choice for these applications. Copper tubes are also easily bent and shaped to fit into tight spaces, which is essential in HVAC and refrigeration installations.

Electrical Wiring

Copper tubes are used in electrical wiring to conduct electricity. Copper's high conductivity and ductility make it an excellent choice for electrical applications. Copper tubes are also resistant to corrosion, which ensures long-lasting performance.

Medical/Dental

Copper tubes are used in medical and dental equipment and devices due to their excellent biocompatibility, antimicrobial properties, and corrosion resistance. Copper tubes are also easily sterilized, which is crucial in these applications.

Automotive

Copper tubes are used in automotive applications, including brake lines and fuel lines. Copper's excellent thermal conductivity and corrosion resistance make it an ideal choice for automotive applications.

Construction and Architecture

Copper tubes are used in roofing and facade systems in construction and architecture. Copper's durability, corrosion resistance, and aesthetic appeal make it an attractive choice for such applications.

Solar Energy

Copper tubes are used in solar thermal collectors to absorb and transfer heat. Copper's high thermal conductivity and corrosion resistance make it an ideal choice for this application.

Industrial

Copper tubes are used in various industrial applications, including heat exchangers, boilers, and process piping. Copper's high thermal conductivity and corrosion resistance make it an excellent choice for these applications.

Telecommunications

Copper tubes are used in telecommunications applications to transmit data signals. Copper's excellent conductivity and resistance to corrosion make it a preferred choice for these telecommunications applications.

Marine

Copper tubes are used in marine applications, including heat exchangers and piping systems. Copper's corrosion resistance and durability make it an ideal choice for these harsh environments.

Choosing the Right Copper Tube Supplier

To ensure you have the most productive outcome when purchasing copper tubes from a copper tube supplier, it is important to compare several companies using our directory of copper tube suppliers. Each copper tube supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each copper tube business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple copper tube companies with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services