Brass is a metallic alloy that is made up of copper and zinc. It has been used for centuries in a wide range of applications due to its unique combination of properties. Read More…

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

With over 25 years of metallurgy experience we guarantee we can produce exactly what you are looking for. We offer fast delivery and a multitude of beryllium copper sizes. Our highly knowledge staff takes great pride in creating these outstanding copper alloys. We have a reputation of manufacturing the best copper fabrications. Our company has risen in the standard in copper processing. Contact...

At Source 21, Inc., we take pride in offering top-notch copper products to meet a wide range of industrial and commercial needs. When it comes to copper, we've established ourselves as a reliable provider known for quality, accessibility, and customer satisfaction. Our extensive array of copper products is designed to cater to your diverse requirements while ensuring uncompromised excellence.

Schorr Metals is a complete metal service center and your best source for copper and brass extrusions, sheets and more with customized fabrication services, cutting, welding and rolling services. Combining our inventory of copper, brass, steel and other metals with our exceptional customer service and capabilities, the answer is clear - Schorr Metals is your choice for quality, service and value.

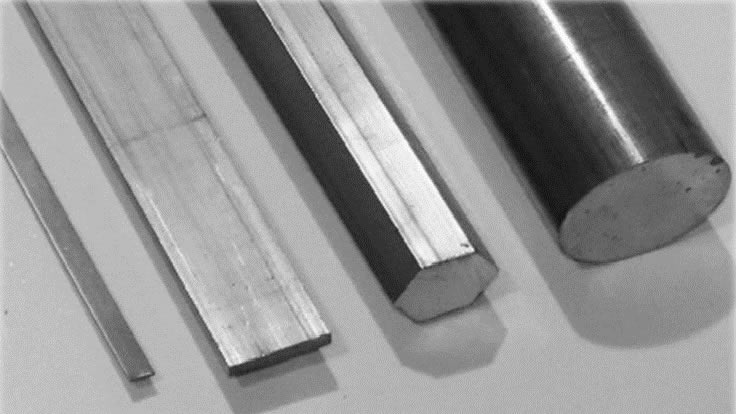

We are committed to our customers. Our engineers manufacture copper products that exceed regulatory standards. Our products are the best quality and adhere to a multitude of rigorous physical testing to ensure the reliability of our copper. You can rest assured that you are receiving the best copper. From tubes, rounds, hollows, squares, hexagons and more, we have it all! Please visit our website ...

More Brass Suppliers

How Brass Is Created and Variations in the Process

Brass is typically made by melting copper and zinc together in a furnace. The traditional process involves melting the copper first and then adding the zinc. However, there are variations in creating brass that involve adding other metals, such as lead or tin, to create alloys with specific properties. The application of adding each of these metals are explained below.

Leaded Brass

Adding lead to brass produces leaded brass, which is more easily machinable and has improved friction properties.

Tin Brass

Adding tin to brass produces tin brass, which is corrosion-resistant and has a yellow color similar to gold.

The process of melting and pouring the brass can also affect the properties of the resulting alloy. Many of these variations, and their specific application, are discussed below.

Sand Casting

This involves creating a mold from sand and pouring the brass into it. Sand casting produces rougher surfaces and less precise shapes, but it is a cost-effective method for producing large quantities of simple parts.

Die Casting

This involves injecting molten brass into a mold under high pressure. Die casting produces more precise shapes and smoother surfaces, making it ideal for producing complex shapes such as gears and valves.

Investment Casting

This involves creating a wax model of the desired shape, coating it with a ceramic shell, melting the wax out of the shell, and pouring molten brass into the cavity. Investment casting produces high-quality, intricate shapes, making it ideal for producing decorative objects and jewelry.

Considerations Regarding Brass

While brass has many benefits, there are also some considerations to keep in mind. One concern is the environmental impact of brass production, particularly when it comes to mining the raw materials needed to make brass. In addition, some health hazards are associated with brass, particularly when it is heated or burned. Finally, despite its corrosion resistance, brass can corrode over time if not properly coated or maintained, particularly in environments with high humidity or exposure to saltwater.

Benefits of Brass

Despite these considerations, brass has many benefits that make it a valuable material for a wide range of applications. Brass is extremely durable and resistant to corrosion, making it an excellent choice for use in harsh environments. Its malleability also makes it easy to form into complex shapes, which is why it is often used in decorative art and sculptures. Finally, brass is fully recyclable, making it an environmentally friendly choice.

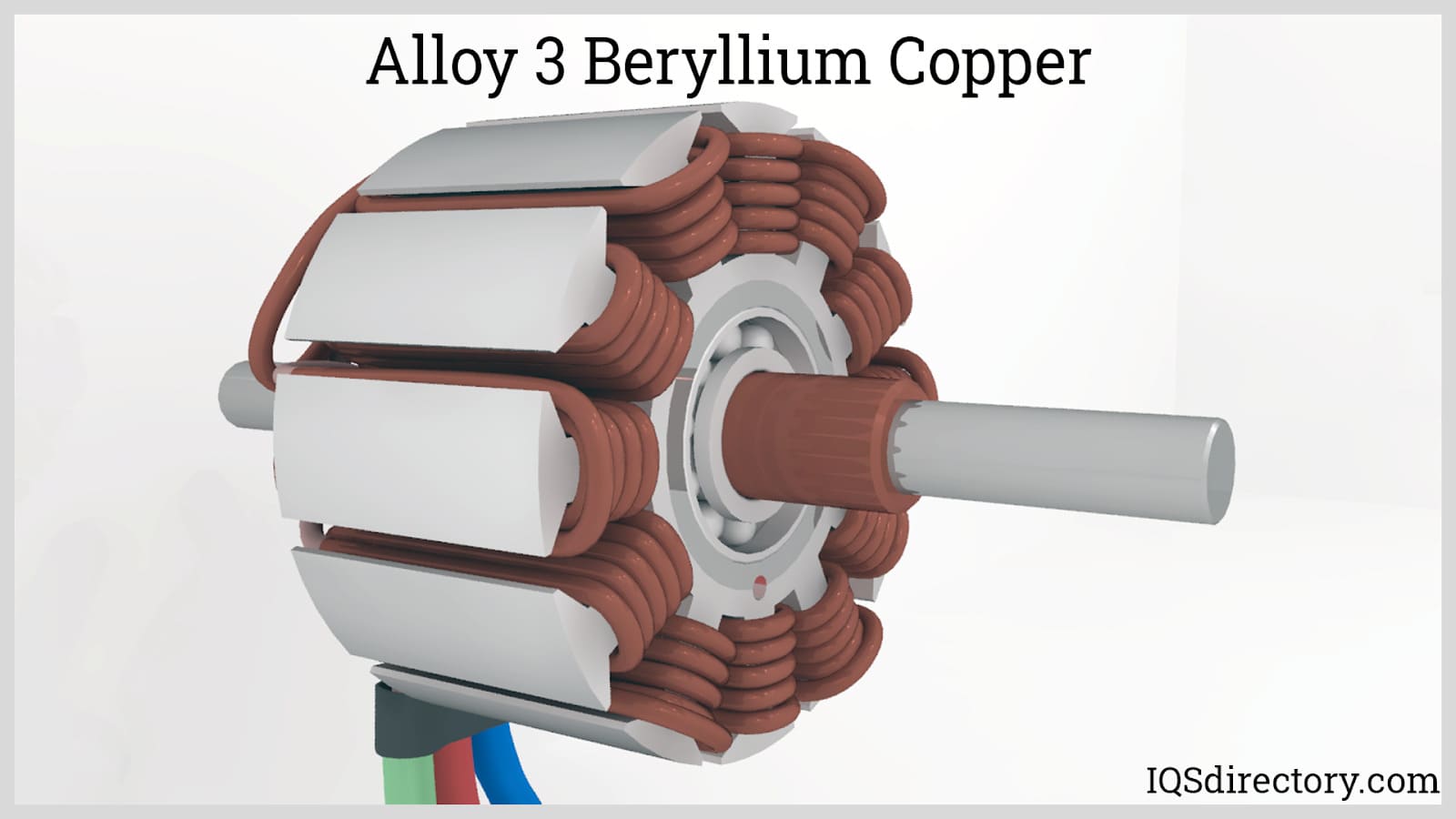

One of the most unique properties of brass is its excellent electrical conductivity. This means that it is able to conduct electricity with high efficiency, making it an ideal material for use in electrical equipment and wiring. Copper is well known for its excellent electrical conductivity, and after adding zinc to create brass, the resulting alloy retains much of this conductivity while also gaining additional benefits such as improved corrosion resistance.

Applications of Brass

Brass has been used in a wide range of applications for centuries. Meanwhile, new applications of brass are constantly being discovered. Some of the most common applications of brass today include:

Architecture and Construction

Brass is often used for decorative features in buildings, such as door handles, railings, and light fixtures.

Plumbing

Brass is commonly used for plumbing fixtures such as faucets and valves due to its corrosion resistance.

Electrical Equipment and Wiring

Brass is an ideal material for use in electrical equipment and wiring due to its excellent electrical conductivity.

Musical Instruments

Brass is commonly used in the construction of musical instruments.

Jewelry and Accessories

Brass is often used in the creation of jewelry and accessories due to its unique color and aesthetic appeal.

Coins and Tokens

Brass has been used in the production of coins and tokens for centuries due to its durability and resistance to wear.

Weaponry and Ammunition

Brass is used in the production of ammunition casings and other components due to its strength and durability.

Marine Equipment

Brass is often used in marine environments due to its corrosion resistance and ability to withstand exposure to saltwater.

Automotive Parts and Accessories

Brass is used in the production of various automotive parts and accessories, such as radiators and decorative trim.

Decorative Art and Sculptures

Brass is a popular material for decorative art and sculptures due to its malleability and ability to hold intricate shapes.

Choosing the Correct Brass Manufacturer

To ensure you have the most positive outcome when purchasing brass from a brass manufacturer, it is important to compare several companies using our directory of brass manufacturers. Each brass manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each brass manufacturer business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple brass manufacturers with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services