Copper pipe is a tube-like structure made of copper. It is commonly used to convey fluids and gasses in various industries Copper pipe has been used for centuries because of its beneficial physical and chemical properties. Read More…

Our company may have started small, but we quickly grew to handle the largest aluminum orders. Our metals are made from the highest quality materials, and we pledge to offer superior service to all our customers. We don’t want customers who use us one time, we want to establish lifelong relationships with customers that last generations. Contact us for more info!

With over 25 years of metallurgy experience we guarantee we can produce exactly what you are looking for. We offer fast delivery and a multitude of beryllium copper sizes. Our highly knowledge staff takes great pride in creating these outstanding copper alloys. We have a reputation of manufacturing the best copper fabrications. Our company has risen in the standard in copper processing. Contact...

At Source 21, Inc., we take pride in offering top-notch copper products to meet a wide range of industrial and commercial needs. When it comes to copper, we've established ourselves as a reliable provider known for quality, accessibility, and customer satisfaction. Our extensive array of copper products is designed to cater to your diverse requirements while ensuring uncompromised excellence.

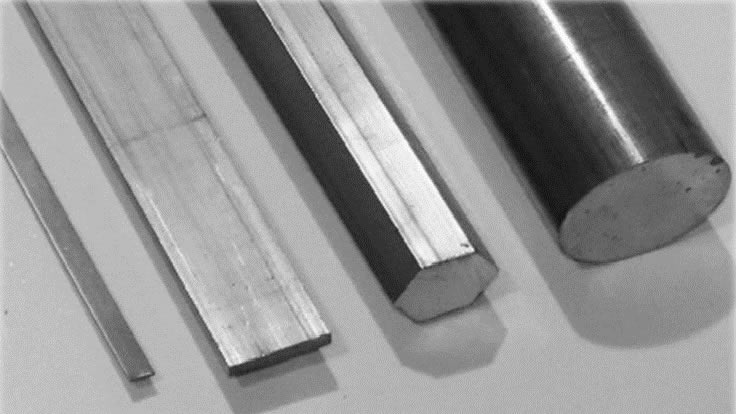

At Concast, we have no problem fulfilling your needs for bars, tubes & shapes in copper alloys. Our complete standard line includes leaded Red Brass, Leaded Tin Bronze, Manganese Bronze, Aluminum Bronze & Extruded products. Plus, special alloys and custom sizes and shapes are easy to quote and to order. When it comes to inventory, we have no equal; we stock more than 875 standard product sizes.

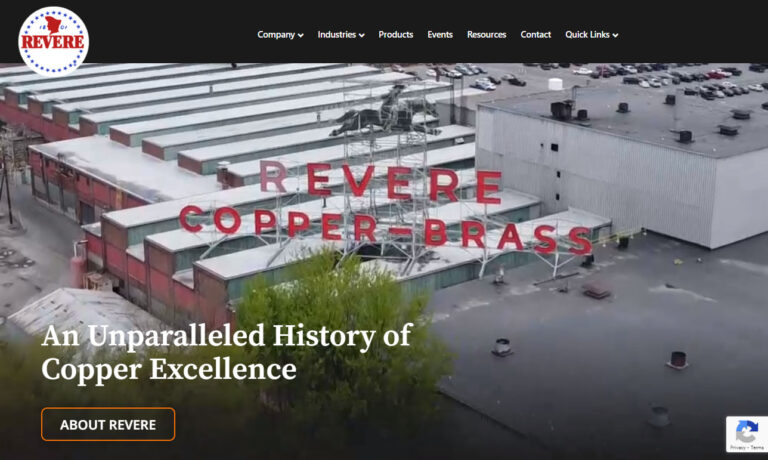

We have history from the American Revolutionary War through today. We are an ISO 9002-certified plate mill. Our copper and copper alloy product selections include copper bar, copper plates, copper sheets, copper strips and extruded profiles. Ask about our brass plates and bronze alloys, too.

More Copper Pipe Suppliers

Why Copper is Used for Pipe Material

Copper is a natural element with excellent physical and chemical properties. It is malleable, ductile, and has good thermal and electrical conductivity. Copper is also resistant to corrosion and has antimicrobial properties, making it ideal for use in piping systems. Compared to other common pipe materials like the plastic polymer, PVC, or steel, copper also has a higher melting point, which makes it less likely to fail under extreme temperatures. Additionally, copper is a non-toxic material and does not emit harmful fumes when exposed to heat or fire.

How Copper Pipe Is Created and Variations of the Process

Copper pipe is created through a series of processes, starting with mining and extraction. Copper ore is mined from the ground, crushed, and refined to produce pure copper. The pure copper is then shaped into tubes through a variety of manufacturing methods, including seamless copper pipe, welded copper pipe, drawn copper pipe, and rolled copper pipe.

Seamless copper pipe is produced by extruding a billet of pure copper through a die, creating a seamless tube. On the other hand, welded copper pipe is created by welding two or more pieces of copper together. Meanwhile, drawn copper pipe is created by pulling a small piece of copper through a die until it reaches the desired length and diameter. Finally, rolled copper pipe is created by rolling a flat piece of copper into a tube shape.

Each variation has its specific application. For example, seamless copper pipe is commonly used in plumbing and HVAC systems due to its high-pressure tolerance and leak-resistant properties. Welded copper pipe is used in industrial applications, where a higher level of precision is required. Drawn copper pipe is used in the electrical industry because of its smooth surface and conductivity. Rolled copper pipe is used in solar water heaters and fire sprinkler systems because of its high-temperature resistance.

Considerations Regarding Copper Pipe

While copper pipe has many benefits, there are also considerations to account for. The creation of copper pipe requires a considerable amount of energy, which can lead to environmental issues. Additionally, copper is more expensive than some other materials used for piping, which can affect the cost of construction projects. Copper pipe can also be subject to corrosion if not installed correctly. This can lead to leaks and other problems in the piping system.

Benefits of Copper Pipe

Despite these considerations, copper pipe has many benefits, including:

Durability

Copper pipes are highly durable and can last for several decades. Copper is resistant to corrosion, erosion, and other types of wear and tear, which makes it an excellent choice for plumbing systems, HVAC systems, and other applications where durability is essential.

Corrosion Resistance

Copper is naturally resistant to corrosion, which means that it can withstand exposure to moisture, acids, and other corrosive substances without corroding or deteriorating. This property makes copper pipes an ideal choice for plumbing systems, especially in areas with hard water or acidic water.

Excellent Heat and Electric Conductivity

Copper is an excellent conductor of both heat and electricity, which means that it can transfer these energies quickly and efficiently. This property makes copper pipes an ideal choice for HVAC systems, electrical wiring, and solar water heaters.

Sustainability

Copper is a sustainable material that can be recycled indefinitely without losing its quality or performance. This property makes copper pipes an environmentally friendly choice for plumbing and other applications.

Bacterial Resistance

Copper has been found to have natural antimicrobial properties, which means that it can inhibit the growth of bacteria and other microorganisms. This property makes copper pipes an ideal choice for plumbing systems, especially in healthcare facilities where preventing the spread of infections is critical.

Aesthetic Appeal

Copper pipes have a unique, attractive appearance that can add a decorative element to homes and buildings. Copper pipes can be used as a design element, either by leaving them exposed or by using them in creative ways to complement the interior design.

Fire Resistance

Copper is a fire-resistant material that does not emit toxic fumes when exposed to high temperatures. This property makes copper pipes an ideal choice for fire sprinkler systems and other applications where fire safety is a concern.

Applications of Copper Pipe

As a result of these beneficial qualities, copper pipe is used in a wide range of applications, including:

Plumbing

Copper pipe is commonly used in plumbing systems because of its high-pressure tolerance and leak-resistant properties.

HVAC Systems

Copper pipe is used in HVAC systems for its excellent thermal conductivity, which allows for efficient heat transfer.

Industrial Applications

Copper pipe is used in industrial applications because of its high-temperature resistance and resistance to corrosion.

Electrical Wiring

Copper pipe is used in electrical wiring because of its high conductivity and durability.

Solar Water Heaters

Copper pipe is used in solar water heaters because of its high-temperature resistance and ability to efficiently transfer heat.

Fire Sprinkler Systems

Copper pipe is used in fire sprinkler systems because of its resistance to corrosion and ability to withstand high temperatures.

Choosing the Proper Copper Pipe Supplier

To ensure you have the most productive outcome when purchasing copper pipe from a copper pipe supplier, it is important to compare several companies using our directory of copper pipe suppliers. Each copper pipe supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each copper pipe business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple copper pipe companies with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services